Pipelines

Meeting increasing demands safely and responsibly

Transporting oil or gas cost-effectively, safely and responsibly to consumers – often via an ageing pipeline infrastructure – is not a simple task.

More and more pipeline systems must traverse remote regions, extreme terrain, or harsh environments, or cross territories that differ in their regulatory regimes and requirements. Onshore and offshore pipelines are an effective and reliable way of transporting hydrocarbons over short and medium distances (x-y km), but they also represent large investments, with design and construction subject to strictly-defined application codes.

Since issuing our first pipeline standard in 1976, DNV has created a series of internationally recognized and award-winning standards, service specifications, and recommended practices. We work in partnership with pipeline operators, contractors, pipe mills, and other stakeholders to continuously improve our services and introduce new technology into our standards and to the pipeline industry.

Our global network of experts can deploy the full range of our experience, expertise, and technology development throughout the lifetime of a pipeline system.

By initiating joint industry projects (JIPs) for pipeline design and operation and investing 5% of our annual revenue in research and development, we work closely with customers to develop new technologies, industry standards and recommended practices.

Concept and feasibility

Our support to customers includes:

- Concept design and early-phase review

- Support for selecting EPC contractors and establishing optimal solutions

- Technology qualification, independent CAPEX/OPEX estimates, and technical cost assessments

- Better understanding of technical risks, and advice on mitigation strategies

- Independent Front-End-Engineering Design (FEED) studies to help unlock potential project value and find the optimal cost-efficient solution

- Qualification of vendors to ensure quality and competitiveness.

Design, construction, installation and commissioning

With detailed design typically managed by contractors, DNV can carry out independent verification or certification, technical studies, material and full-scale testing, on-site inspections, and help ensure pipelines are designed, delivered, and installed in line with governing standards and project specifications, ensuring integrity and quality. Using our in-depth knowledge of standards, we also advise and support our customers to resolve technical challenges.

Operations, life extension and decommissioning

DNV services focus on reducing operating costs without compromising reliability and safety, working closely with operators to establish the most cost-efficient solution for each system.

- Operations planning during the early design phases, building in operational aspects as early as possible, and getting the pipeline ready for operation

- Integrity management for control and documentation of integrity throughout the system’s operational life

- Condition assessment, including defect assessment and global pipeline behavior

- Inspection and maintenance planning — using condition assessments to prioritize inspection and maintenance

- Re-qualification for lifetime extension or change of use, or following modifications and repairs

- Remaining life and life extension studies

- Technical and onsite support for repairs, troubleshooting, interventions, decommissioning, and training.

Related services

Pipeline related publications

Download our whitepapers

Pipeline Insights 2025: Powering Transformation, Mastering Complexity

Discover how the pipeline sector is navigating unprecedented change while strengthening the networks that fuel the energy systems of today and tomorrow.

Related articles

Choosing the best materials to avoid environmentally assisted cracking

Expert advice before the design stage draws on testing and modelling to help specify the right materials for oil and gas equipment.

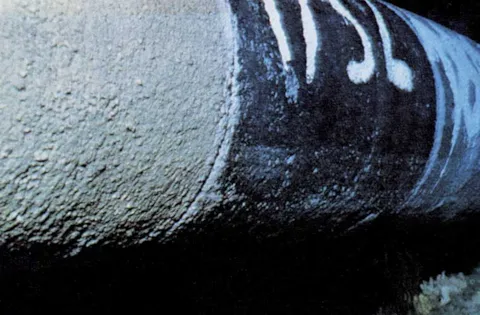

Preventing external corrosion failures

External corrosion is a threat to most equipment in every process facility and deserves closer analysis and prediction than it currently receives.

What causes materials failure in oil & gas and maritime equipment?

Systematic and thorough analysis is required to say with confidence what kind of failure is involved and what led to it

Tubes and piping are the most failure-prone components

In a study of 1,000+ cases in oil & gas and maritime, research by DNV’s laboratories also identify fatigue and corrosion to be the most common modes of component failure.

Meeting the NORM challenges in gas networks

Mixing gases from varying sources in gas networks can raise levels of natural radioactivity in dust and sludge found in pipeline systems, but complete risk-management solutions exist.

Digital pipeline tools: Get your access today

Related information

The Digital Pipeline Ecosystem

The Digital Pipeline Ecosystem seamlessly combines the power of hydraulic modelling, leak detection, integrity management and safety assessment capabilities.

Subsea pipeline design software - Sesam for pipelines

Our subsea pipeline design software offers ultimate strength and fatigue analysis for efficient offshore pipeline design

Laboratories and test sites

Our dedicated experts in laboratories and test sites worldwide are ready to assist you.

Innovation and development

Together with the industry, we help drive the oil and gas sector forward by developing new technical solutions, standards and industry best practices.

Related training courses

Corroded offshore pipelines course (1 day)

Based on DNV-RP-F101, this course is introducing strength assessment of corroded pipelines, including uncertainties associated with in-line inspection results.

Environmental conditions and loads course (2 days)

This course provides an introduction to DNV-RP-C205 covering the necessary steps in the load assessment of marine structures.

Expert hazard awareness training course (2.5 days)

This expert course aims to provide delegates with an understanding of the potential effects and consequences of hydrocarbon releases in the oil and gas industry.

Free span course (2 days)

This course covers DNV-RP-F105, the March 2002 issue and the recent update. The update covers learning from the Ormen Lange project and experience from use of the existing version

Global buckling course (2 days)

The course will give an introduction to the design philosophy of the DNV-RP-F110, how it complements to the DNV-ST-F101, and gives specific requirements for global buckling scenarios of HT/HP pipelines

Hazard awareness training course (1 day)

This 1-day hazard awareness course offers the opportunity for delegates to gain a basic understanding of fires and explosions through a combination of practical demonstrations and lectures.

HAZOP facilitation techniques course (1 day)

This course focuses on facilitation techniques applicable for conducting HAZOP workshops.

HAZOP method training course (2 days)

This course will introduce you to the Hazard and Operability (HAZOP) methodology, essential training if you need to plan, organise, write or manage a HAZOP study.

Introduction to welding for offshore applications course (1 day)

This course will cover the general principles for welding - technology, methods, metallurgy, pipelines, subsea production systems and procedure specifications and qualifications

Materials technology for offshore installations course (online (3 sessions))

An introduction to materials technology applied in the oil and gas offshore industry will be given in this course

Offshore pipeline design course (3 days)

This course will give an understanding of the design philosophy of the pipeline design standard, teach how to perform simple wall thickness design and give an overview of relevant failure modes.

Offshore pipeline integrity management (PIM) course (2 days)

This course provides an introduction to pipeline integrity management, going through the overall risk philosophy and methodology applied

Offshore pipeline overview (2 days)

This introductory course will give a basic understanding of pipelines

On-bottom stability course (2 days)

The new DNV-RP-F109 standard considers the various factors in the seabed environment that affect pipelines, and provides design criteria that applies in order to maximize pipeline stability

Trawling interference course (1 day)

The DNV-RP-F111 covers recommended practices for trawl interference loads, as part of pipeline integrity