Engine room fires - causes, contributors and preventive measures

Statistics show that between 2019 and 2021, there was a sharp increase in engine room fires on board container ships. Preliminary data gathered from public sources indicate that this trend applies to the global fleet – and that for 2022 to 2023, the number of engine room fires remains at the same level as in 2021. This news highlights some common causes and contributors to engine room fires.

Relevant for ship owners and managers.

The increase in engine room fires cannot be seen separately from the increasing number of findings related to dirty engine rooms, missing insulation and screening of oil piping being reported by class surveyors. This is also reflected in the number of PSC detentions related to these issues.

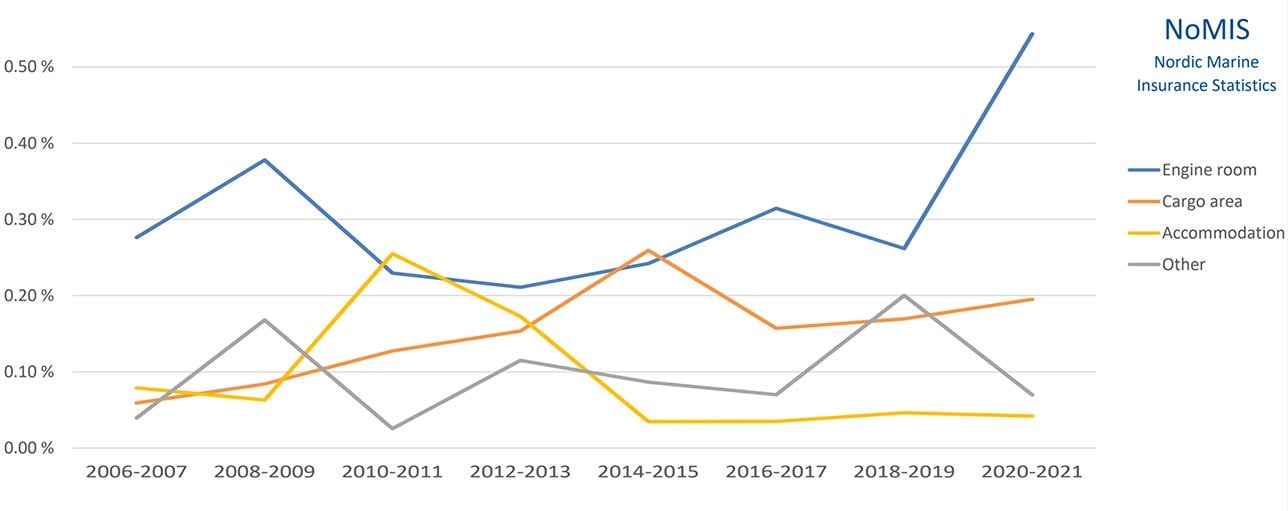

Figure 1: Locations of on-board fires (Source: Cefor (Nordic Marine Insurance Statistics), December 2021)

In connection with the increasing number of engine room fires, the Paris and Tokyo MoUs launched a Concentrated Inspection Campaign (CIC) on fire safety on 1 September 2023 (see news from 8 August 2023). This CIC focuses on the means to controlling and extinguishing fires through fire dampers, fire doors and firefighting systems.

However, to prevent is better than to cure – therefore, we would like to highlight common causes and contributors to engine room fires. Most fires are caused by one of three situations:

1. Flammable oil leaking onto a hot surface

Although it is almost impossible to fully prevent an oil leakage from occurring and reaching a hot surface, proper implementation of the mitigating actions required by SOLAS and class rules will immensely reduce the risk of an oil leakage causing a fire. In short, these entail:

- Insulate hot surfaces with non-absorbing insulation. It is highly recommended to cover insulation with sheet metal plating using the “roof tile” overlap method so that any leakage is led away over the surface of the cover to a safe drain location and does not penetrate the cover.

- Inspect insulated hot surfaces on a regular basis with an (infrared) thermometer or thermal imaging equipment to identify areas where insulation is lacking or insufficient. Do the same after repairs or overhauls to identify locations where the insulation has not been reassembled correctly.

- Screen connections in oil piping properly and, importantly, restore the screening after repairs and maintenance.

- Be careful with the installation and location of flexible hoses. The lifetime of flexible hoses is greatly reduced if installed under stress, extreme heat or subjected to mechanical wear.

2. Electrical fires

Electrical fires often originate in main or distribution switchboard and electrical motors or generators. Although sometimes caused by a component failure, the more common reasons are dirt leading to overheating or short-circuit, or a loose connection leading to arcing. Therefore:

- Perform regular checks of terminal and breakerconnections as part of the planned maintenance and make sure to tighten to the specified torque.

- Regularly clean switchboards and electrical machines.

Figure 2: Fire damage originating from an air circuit breaker failure

3. Mechanical failure

On occasion, a mechanical failure causes a fire, for example through a crank case explosion or hot engine parts being ejected from the engine crankcase.

- Correct and timely engine maintenance and lubrication oil management are essential to prevent such failures.

The size of the fire and the damage caused by it depend largely on three factors: the fuel and oxygen available to the fire and the time until effective firefighting is initiated.

- The fuel available to a fire is not only the oil allowed to escape from a broken pipeline but also the fuel available in the space where the fire is burning. This can be cardboard boxes used to store spare parts, oily rags, oil-soaked insulation and, last, but not least, dirty bilges.

- The oxygen available to the fire depends on the ventilation of the engine room. The sooner the ventilation is stopped, and fire flaps/dampers are closed, the smaller the fire.

- Analysis of multiple fire investigations shows that, without fail, large fires are the result of incorrect or late crew response. Training should always include empowering your crew to handle the situation at their own initiative and not waste time, e.g. looking for the Chief Engineer or asking the Master’s permission to act.

Note that crew response and fire-promoting conditions often go hand in hand, as crew training is reflected in both fire response and housekeeping.

Recommendations

DNV recommends that managers review and, if relevant, update their procedure on engine room fire safety. Valuable input for this can be found in DNV’s updated Fire Safety Awareness brochure, published on DNV.com.

Additionally, we also recommend that our customers use DNV’s PSC Planner to prepare for expected PSC inspections. The PSC Planner, including the additional questionnaire for this year’s CIC on fire safety, is available under Veracity / My Services / Fleet Status.

References

- DNV Technical & Reg News: Port State Control CIC on Fire Safety from 1 September – additional questionnaire available (dnv.com)

- DVN pages on PSC, Port state control (PSC) services (dnv.com)

- DNV Fire Safety Awareness brochure

Contact

For customers:

DATE - Direct Access to Technical Experts via My Services on Veracity.

Otherwise:

Use our office locator to find the nearest DNV office