CO2 Efficient Transport via Ocean - CETO

International climate goals

Carbon capture and storage (CCS) will be a key technology to meet the goals of the Paris and Glasgow Agreements. In other words, CCS must be operationalized at a viable cost.

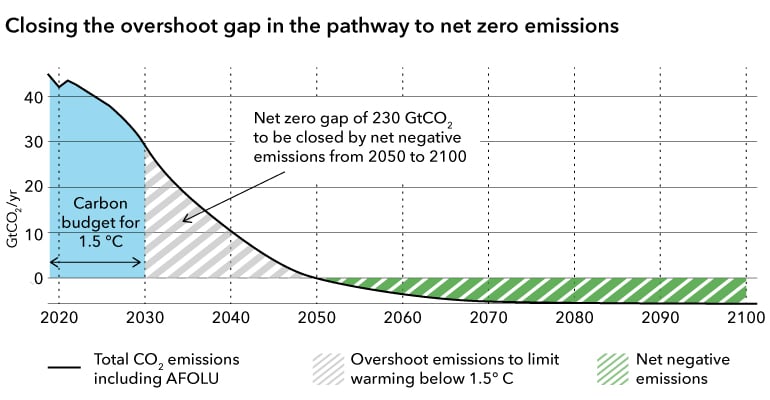

Emission trajectories are foreseeing a period of negative emissions to mitigate the overshooting emissions projected for the next decades. CCS is considered essential to achieving this.

Developing a CCUS value chain

The realization of CCUS depends on getting the cost for each tonne of CO2 injected as low as possible. Effective transport connecting the capture sources to the facilities for use or storage sites is central. The options are pipelines and transportation by ships, and for longer distances ships are considered the most efficient solution.

Today, CO2 is transported at medium pressure (i.e. about 15 bar at –28°C) by smaller ships. Scaling up the vessel size is normally a good way of reducing the transportation cost. However, the relatively high cargo pressure of the medium-pressure LCO2 limits the cargo tank size and, consequently, the potential cost savings from using larger vessels. As a result, technology development and research are needed to enable transportation of large quantities of CO2 at costs that are commercially available.

Operationalizing low-pressure CO2 ship transport

The development of a low-pressure solution for ships with CO2 cargo will enable larger volumes of gas transported through increased tank and vessel sizes. A low-pressure transport system (approx. 7 bara at –49°C) enables a larger ship tank diameter, flexibility in cargo hold arrangement, increased cargo capacities and presumably reduced transportation costs.

At the same time, moving towards a low-pressure solution lowers the design temperature and reduces the margin to the triple point (approx. 5.2 bara, -56.6 °C), adding new risks and challenges. At the triple point, the CO2 can be present in solid, liquid and gas phases. This has potential implications on the transportation chain. A reduced margin to the triple point leads to an increased risk of dry ice formation, which may threaten the reliability of cargo handling operations.

Another challenge with a low-pressure solution is the low temperature. Identifying suitable materials for the entire value chain – such as cargo piping, storage tanks and a liquefication plant – is therefore vital to operationalizing a low-pressure value chain. For the containment system, extra-high-tensile steel is anticipated to be a possible solution for increasing the tank size while limiting the cost. However, the performance at a low temperature needs to be proven.

The CETO project’s different activities will explore these challenges, and the goal is to develop safe and technically feasible solutions.