Approach for hazard identification

Assessments such as Hazard and Operability (HAZOP), Hazard Identification (HAZID), Process Hazard Analysis (PHA), and Layer of Protection Analysis (LOPA) are essential for ensuring the safety and reliability of operation in the process industries. These exercises involve technical professionals who identify the most significant hazards present within a unit, based on hazardous (flammable and toxic) materials, their volume, storage conditions, and potential cause of loss of containment. This is a key step as identifying hazards present on a site and in its operations help prevent or reduce the potential accidental releases of hazardous materials.

Estimating the possible consequences during a process hazard analysis is usually done in a qualitative manner.

| No. | Primary Guideword | Secondary Guideword | Potential Hazard | Failure Mode / Cause | Unmitigated Consequences | Safeguards |

|---|---|---|---|---|---|---|

No.1

|

Primary GuidewordLoss of containment |

Secondary GuidewordJoint / Fitting

|

Potential HazardY

|

Failure Mode / CauseJoint Failure

|

Unmitigated Consequences

|

Safeguards

|

When more accurate evaluation of the potential consequences of low-consequence hazards, or when a more thorough assessment of these hazards is required, quantitative analysis of release scenarios can be performed. This is where our Phast software becomes applicable.

Consequence estimation using the Phast™ software

Our Phast consequence analysis software is suitable for the process industry. It uses validated mathematical models to simulate the behaviour of hazardous substances upon release, considering factors such as type of release, the properties of the substances, and weather conditions. The software provides comprehensive results and visual representation in the form of graphs for discharge, dispersion, thermal, overpressure, and toxic effects.

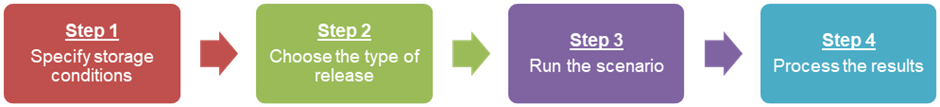

A typical workflow within Phast involves the following steps:

By following the steps above, technical professionals can estimate the potential consequences of hazardous releases.

The inputs necessary for performing consequence modelling in the Phast software are typically obtained from:

- Process and instrumentation diagrams (P&IDs)

- Process flow diagrams (PFDs)

- Plot plans

- Heat & mass balances

- Equipment ratings and data sheets

- Operating procedures

| No. | Primary Guideword | Secondary Guideword | Potential Hazard | Failure Mode / Cause | Unmitigated Consequences | Safeguards |

|---|---|---|---|---|---|---|

No.1

|

Primary GuidewordLoss of containment |

Secondary GuidewordJoint / Fitting

|

Potential HazardY

|

Failure Mode / CauseJoint Failure

|

Unmitigated Consequences

Quantified Results:

|

Safeguards

|

In addition to numerical calculation results, the Phast software provides visual representation of the consequences, which are commonly reviewed during a process hazard analysis. The visualisation of results is crucial during workshops and Phast facilitates this by allowing for consequences results from release scenarios to be overlaid on satellite imagery or plot plans. This feature provides technical professionals with confidence when evaluating hazardous scenarios.

For example, the figure illustrates the thermal radiation hazard ranges for multiple radiation levels. This demonstrates the value of Phast in providing a clear understanding of potential hazards during hazard workshops.

Explore our software solutions:

Discover other applications of our software:

Hydrogen consequence and risk modelling

Guidance on modelling hydrogen releases using Phast and Safeti software.

CO2 consequence and risk modelling

Guidance on modelling carbon dioxide (CO2) releases using using Phast and Safeti software.

Accident & incident investigation

Assess hazardous material releases, identify root causes, and develop preventive measures using the Phast software.

Emergency response

Simulate consequences from loss of containment scenarios to aid in the development of effective emergency response plans using the Phast software.

Regulatory compliance

Evaluate and manage consequence and risks associated with hazardous materials and operations for regulatory compliance using the Phast and Safeti software.

Facility siting & occupied buildings risk assessments

Support operators in conducting Occupied Buildings Risk Assessments (OBRA) for major hazard installations using the Safeti software.

|

HAZOP stands for Hazard and Operability Study. It's a systematic method used to identify potential hazards and operability issues in industrial processes and systems. HAZOP is commonly used in industries such as oil and gas, chemical manufacturing, pharmaceuticals, and process engineering. It is applied during the design and operation of processes, systems, and facilities to identify potential hazards, operability issues, and deviations from the intended design. |

|

HAZID stands for Hazard Identification, which is a systematic process used to identify and assess potential hazards associated with a particular activity, process, or system. It aims to identify potential sources of harm or adverse effects to people, property, or the environment. HAZID is typically used in industries such as oil and gas, chemical manufacturing, and construction to identify potential hazards and risks associated with projects, operations, or facilities. It helps in the early identification and assessment of hazards to implement preventive measures and ensure safety. |

|

PHA stands for Process Hazard Analysis, which is a systematic method used to identify and analyse potential hazards in industrial processes. It involves identifying potential scenarios that could lead to accidents or incidents, assessing the likelihood and severity of these scenarios, and implementing measures to mitigate or eliminate the identified hazards. PHA is commonly used in industries such as chemical manufacturing, oil and gas refining, and pharmaceutical production to ensure the safety of operations and personnel. |

|

LOPA stands for Layer of Protection Analysis. It is a structured method used primarily in the process industries, including oil and gas, chemical manufacturing, and pharmaceuticals, to assess and analyse the effectiveness of layers of protection against identified process hazards. LOPA helps determine the adequacy of existing safeguards and the need for additional protective measures to prevent or mitigate potential accidents or incidents. It is typically applied during the design and operation of process facilities to enhance safety and reduce risks associated with hazardous processes. |

|

Phast is a software tool developed by DNV, that is designed for consequence analysis of hazardous events. It simulates the behaviour of hazardous substances to assess potential outcomes like fires, explosions, and toxic releases. |