The most comprehensive hydraulic modeling software for gas networks

Trusted by pipeline engineers worldwide for 50+ years, Synergi Gas delivers unmatched accuracy and reliability for networks of any size and complexity.

Why pipeline engineers worldwide choose Synergi Gas

Synergi Gas provides the precision and confidence you need to design, analyze, and optimize gas networks while meeting today's regulatory and operational challenges:

- Handle Extreme Complexity: Model networks of 1,000,000+ nodes with industry-leading computational power

- Ensure Regulatory Compliance: Meet strict safety and reporting requirements with detailed pressure analysis

- Reduce Operational Risks: Identify potential issues before they impact your network

- Optimize System Performance: Minimize energy consumption while maintaining reliability

- Future-Proof Your Infrastructure: Confidently plan for hydrogen blending and renewable gas integration

Comprehensive modelling package for pipeline engineering excellence

| Feature | Synergi Gas Capability |

|---|---|

FeatureNetwork Scale |

Synergi Gas CapabilityFrom small distribution, gathering, and transmission systems to large networks with 1,000,000+ nodes |

FeatureAnalysis Types |

Synergi Gas CapabilitySteady-state, extended period simulation, transient, thermal |

FeatureGas Compositions |

Synergi Gas CapabilityNatural gas, hydrogen blends, biogas, CO₂, ammonia, custom mixtures |

FeatureEquations of State |

Synergi Gas CapabilityAGA, GERG-2008, Peng-Robinson, Redlich-Kwong, and more |

FeatureIntegration Capabilities |

Synergi Gas CapabilityImport data from SCADA, GIS, CIS, and enterprise systems |

FeatureComputational Performance |

Synergi Gas CapabilityMulti-threading support for complex simulations |

FeatureReporting |

Synergi Gas CapabilityCustomizable templates aligned with regional regulatory formats |

Discover applications of our software

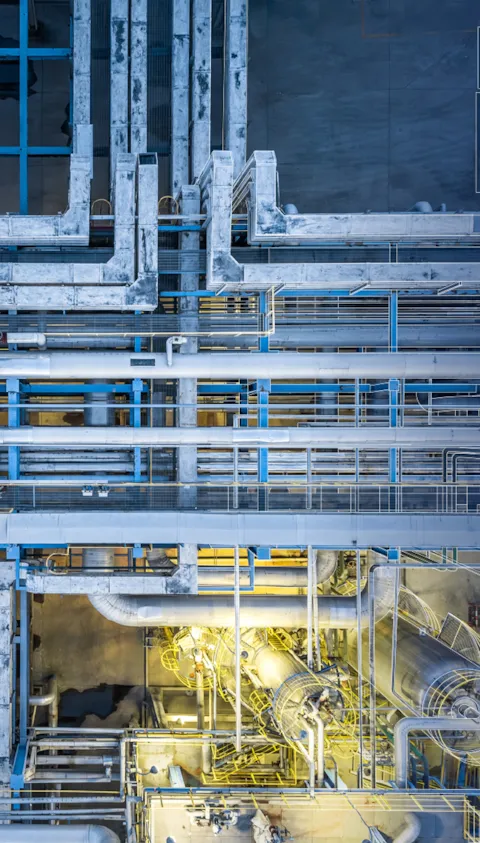

Optimizing compressor fuel consumption

Transform your compressor station operations, minimize fuel consumption and maximize throughput with Synergi Gas

Peak Shaving Analysis for LNG/CNG injections

Discover how Synergi Gas can help you optimise your peak shaving analysis and optimize LNG/CNG injection points with Synergi Gas

Emergency Planning for Gas Networks

Synergi Gas helps gas utilities and network operators respond quickly and effectively in emergencies, from severe weather events to equipment failures

Overpressure protection assessment

Learn how Synergi Gas can deliver comprehensive hydraulic analysis and automated overpressure assessment for your gas distribution system

Model building from GIS

Discover how Synergi Gas modules can revolutionize your model building workflow and turn your existing spatial investments into competitive advantages

Robust modules for enhanced capabilities

Synergi Gas has extensive core steady-state modelling functionality out of the box, but sometimes more is needed. To meet your expanding needs, Synergi Gas has 10 purpose-built modules that work seamlessly:

Trusted by pipeline engineers worldwide

The Synergi Gas advantage for network analysis and hydraulic modelling

- Comprehensive commercial off-the-shelf software with an intuitive user interface

- World-class technical support and training

- Unrivalled program configurability and flexibility

- Extensive selection of powerful “snap-on” modules

- Capable of handling the largest models in the industry

- Models gathering, transmission and local distribution systems

- Integration with GIS, CIS, and other important systems

- Open model data formats always ensure data access

Simulation and optimization services

With a unique blend of domain expertise, our vast experience our analysts and consultants help you harness the full potential of your pipelines.

Find the right network modelling and pipeline simulation tool

View our product comparison

Synergi Gas training

Asset simulation and optimization

Frequently asked questions about Synergi Gas software:

|

With Synergi Gas from DNV you can quickly build a model of your new pipeline, either by hand or in a more automated fashion with CAD drawings or GIS data. If terrain is significant, there are several methods available to assign elevation data along your proposed pipeline. Enter the pipeline data, properties of the gases, projected meters for consumption, and supply pressures to complete the model in the hydraulic circuit design software. The Synergi Gas Steady-State engine will quickly return the calculated pressures throughout the system. If the results prove that you need additional compression, the program includes a tool for determining the number of compressor stations required, along with the recommended spacing between them. Once you’ve received the compressor curves from the vendor(s), you can input this data into Synergi Gas for a more accurate model of the compressor station behaviour. Finally, if you really want to get the most out of your new pipeline, you can take that same model used for the steady state analysis and also run a transient analysis using the Unsteady State module in Synergi Gas, so that you can plan how to maximize the line pack available. |

|

Absolutely. You can replicate the event in DNV’s Synergi Gas software by modelling the rupture location along with the pressures and flows at the time of the rupture. The Unsteady State module transient analysis will provide you with a complete picture of the resulting pressures and volume of gas lost. You can then try alternate measures – interrupt fewer customers, close a different set of valves, and so on – to assess how the outcome may have changed. You can then apply this knowledge to additional scenarios throughout the gas distribution system. For low pressure systems, the steady-state analysis is appropriate for line break models. However, a low-pressure distribution system presents a different set of challenges due to the sheer number of isolation valves that are available. For very interconnected systems, it may be difficult to quickly tell not just which valves need to be closed, but also what the hydraulic impact is of these closures. The Synergi Gas Area Isolation module in Synergi Gas solves this problem by showing you the required valves for closure to isolate any pipe or zone of your choosing. And if you’re using the Customer Management module, the program can generate a list of the affected customers, along with their contact information and load characteristics. |

|

Aside from Model Builder module and the Customer Management module in Synergi Gas, automating the module building and load generation process, Synergi Gas offers ways to help you work smarter. For example, you can combine studies under one model using flow categories for various load scenarios, and partial sets for your system reinforcement options, allowing you to quickly view any combination of analyses, including reports and charts with your results. You can also use Version Management if you have multiple users of the hydraulic modelling software, and it becomes difficult to keep track of changes to your master model. Version Management sets up a library with user permissions that tracks add, modify, and delete transactions in a parent (base model) / child (versions) relationship. Any change to the parent gets inherited by the children, and any changes to the children can be promoted to the parent. |

|

Synergi Gas software from DNV can help determine if other low pressure stations can help distribute the shortfall through distributed relief and provide associated pressures within the network as well as identify bottlenecks in the gas distribution system. |

|

YES! We have a relatively new module in Synergi Gas called the Regulator Station module which helps you ensure your safety equipment protects your downstream gas distribution system. It helps you prove compliance by analysing station header, branch, and stack piping, as well as failed regulator and relief capacities at MAOP and MOP pressure levels. Please contact your DNV - Software Sales sales representative for a demo today. |