Containers on bulk carriers – a practical guidance

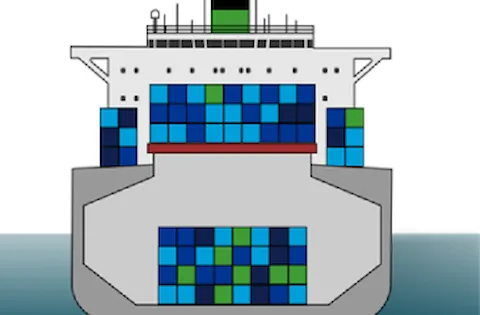

Carriage of containers on bulk carriers is a hot topic, and careful planning and preparation is necessary to ensure the safety of the crew, ship and cargo. This technical news provides you with the relevant information for preparing a bulk carrier for the carriage of containers.

Relevant for ship owners, managers, design offices and shipyards of bulk carriers.

Structural strength

The main deck and hatch covers on modern bulk carriers usually have a structural capacity of around 2.0 to 2.5 t/m2 of uniformly distributed load (UDL). The challenge is that the main deck and the hatch covers are not designed to take the point loads from the containers and the cargo securing equipment. Local supporting structures for the container socket and/or other lashing devices must be considered. In addition, the transverse and longitudinal hatch cover stoppers may need to be modified.

Bulk carrier cargo holds are designed for large loads from bulk cargo, and the overall strength is more than sufficient to carry the relatively light containers. However, the same challenge with point loads as for the deck and hatch covers applies.

Stability documentation

If the containers are stowed in the holds only, the existing stability calculation and resulting metacentric height (GM) limit curve covers the transport of containers. The loading condition with containers must comply with existing stability limits.

When containers are carried on deck, compliance with applicable stability and longitudinal strength criteria in deck cargo loading conditions must be shown in updated/amended stability manuals. In general, intact GM limit curves shall be recalculated considering the additional wind profile area from the containers.

Probabilistic damage stability calculations may also be required for ships with reduced freeboard (B-60/B-100), see IACS UI LL65. For ships with B freeboard (without reduction), it may be necessary to reassess the damage stability calculations of SOLAS Chapter XII (flooding of single holds), depending on how compliance was documented originally.

Loading computer

The Loading Computer System (LCS) will have to be updated as necessary with new GM limits, profile curves or other stored data. In cases where the ship does not need any new limits or data, a test condition with deck cargo shall be provided. Please note that some LCS do not support non-bulk cargo and deck cargo.

Cargo securing

The stowage and securing of cargo other than bulk cargo is to be described in an approved Cargo Securing Manual (CSM). Many bulk carriers already have such an approved manual because they are intended for carriage of breakbulk, e.g. steel coils. With the information given in the CSM, the crew can design and execute a safe cargo securing of containers.

The CSS Code Annex 1 specifies lashing methods for two tiers of containers. If three tiers or more are intended, the container lashing method must be shown in a container securing arrangement and be submitted for approval. If the intended container loading conditions vary in terms of number of container tiers, container weights, or floating conditions of the vessel, an approved lashing computer system would be required.

Fire safety

Cargo holds shall in general be equipped with a fixed gas fire extinguishing system, typically a CO2 system. However, some bulk carriers have a flag state exemption for such a fire extinguishing system, as they are designed for non-combustible cargo only. Containers are in general combustible, hence a gas fire extinguishing system in the cargo holds is required. The exception is empty containers, which constitute low fire risk and should, in DNV’s opinion, be permitted. However, this exception must be accepted by the flag administration.

Dangerous goods

In case the vessel is intended to carry containers containing dangerous goods, SOLAS Chapter II-2 Regulation 19 must be observed, and the vessel must be equipped and certified accordingly. The stowage and segregation requirements of the IMDG Code must be observed when planning the container stowage.

Navigation

If containers are carried as deck cargo, bridge visibility (SOLAS V Reg. 22) and COLREG requirements must be considered. The so-called castle stowage of containers obstructing max permissible blind sectors for visibility is normally not accepted.

Safe access

Safe access to the container cargo needs to be observed to allow for monitoring of securing arrangements during the voyage. Under-deck spaces must be accessible and provided with ventilation, illumination, and atmosphere check to allow safe access.

Mooring and towing equipment

The side projected area of containers stowed on deck and hatch covers is to be considered for the selection of mooring and towing lines, and for the loads applied to shipboard fittings and supporting hull structure.

Class notations

It is recommended that you apply the class notation Container, which provides a design standard enabling the safe and reliable transport of containers on ships, especially if three or more tiers of containers are intended.

It is also recommended that you ensure compliance with the Code of Safe Practice for Cargo Stowage and Securing (CSS Code) Annex 14 by assigning the class notation Safelash.

Typical documentation requirements for container cargo can be found in the Appendix.

Recommendations

The recommendations in this newsletter summarize key issues for bulk carriers carrying containers. We recommend that you review these items related to your ships and existing procedures.References

Appendix

Annex I: Typical documentation requirements for carriage of containers on bulk carriers (see on page 3 in PDF version of this technical news)

Contact

- For customers:

DATE - Direct Access to Technical Experts via My Services on Veracity. - Otherwise:

Use our office locator to find the nearest DNV office.