Developing the analysis engines for Synergi products

Synergi software products’ analysis engines have evolved over the past 50 years to support market-leading solutions for the oil and gas industry.

Synergi software products’ analysis engines have evolved over the past 50 years to support market-leading solutions for the oil and gas industry. DNV continues to enhance these analysis engines as we move forward in the development process for the next generation of Synergi software products. For this blog post I am delighted to introduce you to our guest blogger Andrew Daniels. Andrew, who is based in our Mechanicsburg, Pennsylvania office, is a Principal Software Development Scientist on DNV’s Analytics, AI & Data Science (AA) team. He has extensive experience in developing analysis engines and enhancing the analytics behind them.

Here, Andrew describes the efforts of the AA team as they work to develop analysis engines for the next generation of Synergi products.

Analysis engines development for next generation Synergi products

Developing analysis engines for next generation Synergi software

You have probably used Synergi Gas or Synergi Pipeline Simulator. Have you ever wondered what is involved in developing the underlying analysis engines? For more than 50 years, DNV’s AA team has been enhancing the analytics behind these products.

So, are we finished yet? No! There is still much to do. DNV is currently re-writing its hydraulic analysis applications. The AA team is working on several important projects to support this effort. Please join me on a virtual tour through the efforts of the AA team as we bring our products to the next generation.

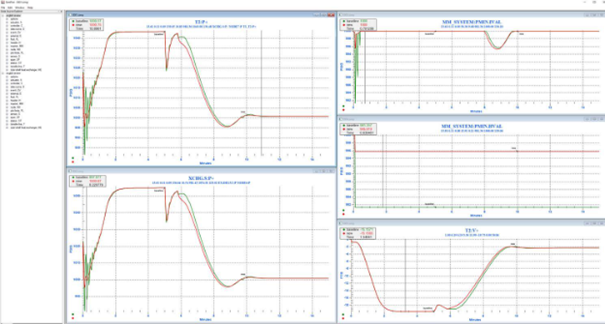

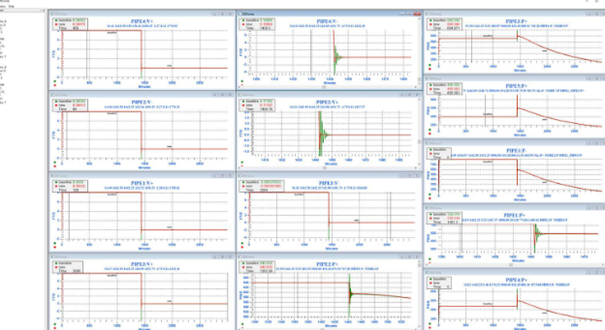

Step doubling: An exciting new approach to high caliber transient pipeline simulations

What is Step Doubling? Step Doubling may sound like a trivial term. It is actually an extremely powerful mathematical technique. We use Step Doubling to solve a system of partial differential equations in a manner that is both more stable and second order correct.

The idea to use Step Doubling began with Dr. Todd Dupont, a professor at the University of Chicago. He implemented the pipe equations within Synergi Pipeline Simulator in 1969. Yet, it bothered Dr. Dupont that this solution of equations is not second order correct. He kept his eyes open for better techniques. Finally, he found what he was looking for: Step Doubling. Dr. Todd Dupont and Dr. Richard Myers introduced Step Doubling to the pipeline industry during the 2019 PSIG conference in London, England. Interestingly, this was almost exactly 50 years after he implemented his original technique. Dr. Myers is currently implementing Step Doubling within Synergi Pipeline Simulator.

Step doubling: An exciting new approach to high caliber transient pipeline simulations

So, what does it mean for the solution to be second order correct? I am not going to bore you with a lot of equations here. Basically, simulations using Step Doubling converge more quickly to the true solution of the underlying equations than the original method, which should result in simulations using Step Doubling being generally more numerically stable than the original approach. Also, simulations should be able to take larger time-steps with the same accuracy as the original method.

Common domain model and common components: The “glue” that unite DNV’s hydraulic analysis engines

For over three decades we wanted to bring Synergi Gas, Synergi Pipeline Simulator, and Synergi Liquid closer together. These products were originally developed by separate companies. DREM, founded in 1969, developed the Synergi Pipeline Simulator. Stoner Associates, founded a year later, developed Synergi Gas and Synergi Liquid. These companies merged in 1985. Ever since this merger we understood the synergies between these products. Wouldn’t it be nice to be able to run analyses using any of these products on the same data set?

We are currently developing our next generation hydraulic products. This product transition gives us a unique opportunity. We can now configure the interfaces of all the analysis engines to live off the same data set. This will allow applications to call any of the analysis engines using the same data store. In other words, for the first time we will be able to run Synergi Pipeline Simulator and Synergi Gas on the same model. We are taking a two-pronged approach to make this happen through the common domain model and common software components.

The common domain model consists of two types of data. The first type is a set of common attributes shared among all the analysis engines. The second is a set of attributes that are specific to particular analysis engines.

For example, all pipes have diameters and lengths. The application will store these diameters and lengths within a central database. Each application will use the exact same pipe diameters and lengths for the analysis. This is true whether the simulation is a detailed Synergi Pipeline Simulator simulation or Synergi Gas analysis.

Other attributes, such as PID controller information, are only required by a subset of the analysis engines. These attributes will be fed to the analysis engines that need them and will be ignored by engines that do not need them. In this way, the common domain model enables the pipeline and distribution planning analysis tools to be fed with the same data set.

The second approach to unifying the hydraulic analysis engines is through common components. We use common components to reduce the modeling differences between our analysis engines. PrimeMover is an example of one of the common components we are developing.

Developing Analysis Engines for Compressor and Pump Stations

Our current products model compressor and pump stations very differently from each other. We build stations in Synergi Pipeline Simulator using many individual devices. We build stations in Synergi Gas by placing all the details within a single compressor station facility.

Developing Analysis Engines for Compressor and Pump Stations

How can we make these products live off the same data set when they are so different? The answer is to use a common compressor and pump analysis package. We are developing PrimeMover, a compressor and pump analysis tool. This tool will solve the compressor and pump equations inside each of our analysis engines. PrimeMover will allow each analysis engine to live off the same data set. It also will enhance the consistency in results between the analysis engines.

I am very excited about the projects we in the AA team are working on. They should provide valuable benefits to the next generation products. The common domain model and common components will finally unite our products into a seamless set of offerings. Step Doubling will continue our legacy for offering high quality simulation capabilities.

I hope this post gives you some insight into what is going on in DNV’s AA team. I would be happy to hear any comments or feedback on this post.

Author: Andrew Daniels

9/25/2020 1:52:21 PM