Hydrogen flow laboratory

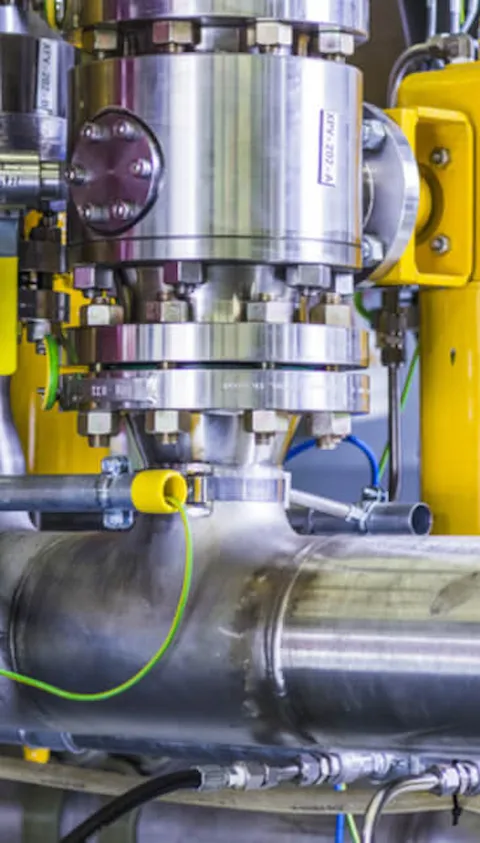

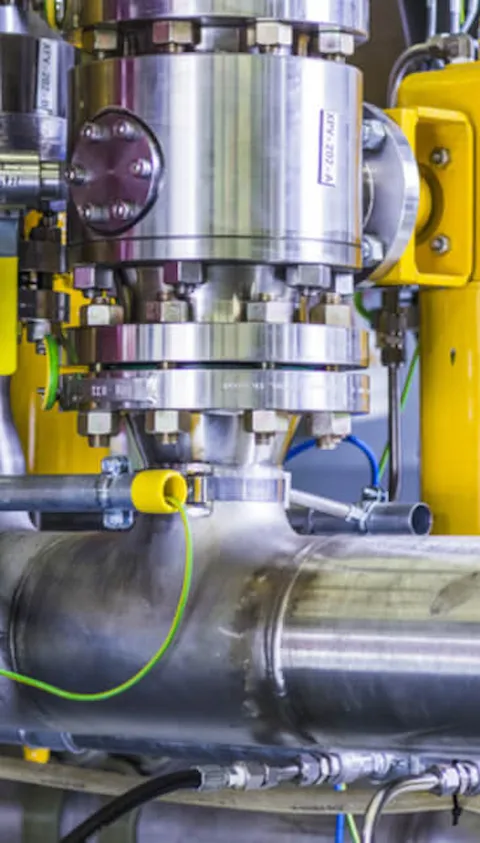

The accurate measurement of hydrogen flow is developing fast More and more industrial systems are designed to transport hydrogen on a commercial basis and even high-pressure hydrogen networks are proposed. The transport and subsequent fiscal transactions require the use of accurate metering systems. It is known that due to the large change in physical properties between natural gas and hydrogen, existing natural gas-based technologies may not work under these new hydrogen conditions. The energy industry strongly demands solutions for the verification of these emerging flow technologies. For this purpose, DNV has built a hydrogen test facility called HyFLG at the Technology Center in Groningen.

Specifications HyFLG

The facility is based on a closed loop system and uses a specially designed blower concept that is able to generate stable flows up to 500 m3/h at pressures up to 40 bar(a) under a range of gas compositions, including 100% hydrogen. With this new development, DNV offers its customers an opportunity to test various flow measurement technologies in a safe way under realistic operating conditions. For testing the metrological performance, DNV make use of a specially developed flow reference. This flow reference is based on a 4” turbine flow meter that uses the PTB turbine meter model to allow the transferability under different gas compositions. The basic specifications and layout of the flow loop, including the test capabilities are listed in table below HyFLG flow loop specifications.

HyFLG flow loop specifications |

|

| Pressure | 5-40 bar(a) |

| Temperature | Ambient conditions (15°C -25 °C) |

| Flow rate | 5-500 m3/h |

| Gas composition | 0-100% for H2, N2, CH4 (and blends) |

| Test section diameter | 1-6 inch |

| Reference uncertainty | 0.3% high Re, 0.5% low Re |

| Technologies | USM, Turbine, Rotor, dP, Coriolis* |

| *limitation in max. differential pressure of 60 mbar | |

|

|

Specification all-gas flow laboratory

In addition to the development of the HyFLG, DNV has upgraded its existing Multiphase Flow laboratory, enabling clients to test gas mixtures up to 30% hydrogen at high pressure (33 bar(a)) and high flow rates (1000 actual m3/h). The newly developed flow reference system, based on a combination of sonic nozzle, Coriolis and turbine meters, has a very low calibration uncertainty and transferability of 0.14 % on all gases (N2, CH4, CO2, natural gas and natural gas blends up to 30% hydrogen).

All-gas flow loop specifications |

|

| Pressure | 5-33 bar(a) |

| Temperature | 15°C -25 °C |

| Flow rate | 5-1000 am3/h |

| Gas composition | 0-30% for H2, N2, CH4 (blends), 100% CO2 |

| Test section diameter | 2-8 inch |

| Reference uncertainty | 0.12%-0.15% |

| Technologies | USM, Turbine, Rotor, dP, Coriolis |

|

|