Study shows DNV’s Smart Cable Guard can reduce grid outage time by 55%

Analyses by a German distribution system operator and DNV shows DNV’s asset monitoring platform can reduce outage time while providing a positive return on investment

Rheinische NETZGesellschaft (RNG), a German network operator, wanted to prevent faults in its cable network to keep downtime to a minimum. A joint study by RNG and DNV showed that DNV’s Smart Cable Guard monitoring platform, can reduce outage time by 55% with a positive return on investment.

Rheinische NETZGesellschaft (RNG) is the network operator for the city of Cologne and Germany's Rhineland region and manages electricity, gas, heating and water networks with a total length of over 30,000 kilometres. The rise of e-mobility, new housing developments, the expansion of commercial and industrial areas, as well as distributed renewable energy supply such as wind and solar, will increase capacity and require flexibility of the electrical load in distribution grids. Simultaneously, RNG is faced with the challenge of maintaining existing cable assets optimally and renewing them in a resource-efficient way. To continue improving the quality of supply and increase its capacity, as required by Germany’s federal network regulator (BNetzA), RNG needs to detect potential faults as early as possible and keep downtime to a minimum.

In the past, RNG applied on Fault Passage Indicators (FPI) and intelligent (secondary) substations equipped with Distribution Automation (DA), to reduce outage time in their power grid. However, FPIs still require additional time from engineers to locate the actual fault along a cable circuit. DA allows the network control centre to reroute power if faults occur. But DA comes with a high price and can therefore only be installed on a select number of (secondary) substations. The Smart Cable Guard system is a promising alternative here.

In 2019, RNG installed DNV's Smart Cable Guard (SCG), a 24/7 fault prevention and detection system, in three of their cable circuits in Cologne. SCG is an asset monitoring platform which provides:

- Alerts about detected weak spot including a risk level indicating when preventive maintenance action is needed – weak spots are identified based on detected partial discharges (PDs) or intermittent faults

- Alerts about detected short circuit faults due to, for example, excavation works

- Accurate location (within 1% of circuit length) of any detected weak spot or fault

- Information about the overall healthiness of the cable circuit

With FPIs and DA already in place at some parts of its network, RNG wanted to quantify additional benefits that SCG could bring in terms of costs and benefits.

Smart Grid cost-benefit analysis

Together with the consultants from DNV’s Smart Cable Guard, a cost-benefit model was developed for one of RNG’s rather small substations with 15 outgoing cable feeders. This model evaluated both the existing technologies and the Smart Cable Guard platform against operational and investments costs versus financial benefits.

For the creation of a cost-benefit model, a characteristic area of the RNG network was selected. This area consisted of a substation with fifteen outgoing cable circuits labeled A to O, totaling a length of 42 km, serving 122 secondary substations/RMUs and carrying a total load of 15.7 MW.

The fifteen outgoing cables were configured as open rings whereby each cable circuit had at least one alternative feed for a fast (partial) resupply after a fault. Other parameters used, based on the experience of RNG and DNV experts, were for instance: approx. 20% of the cable faults are caused by external influences; the average interruption duration is 40 minutes; DA will reduce the interruption duration for the cable section that has no fault by 95%. The cost of each technology consists of system hardware and installation capital costs (depreciated over 10 years) as well as the annual operational usage and service costs. For DA, only the costs of the remote control were considered and not the costs of the motorized switch. The benefits of each technology were calculated based on the cost of the avoided outage time per minute and load.

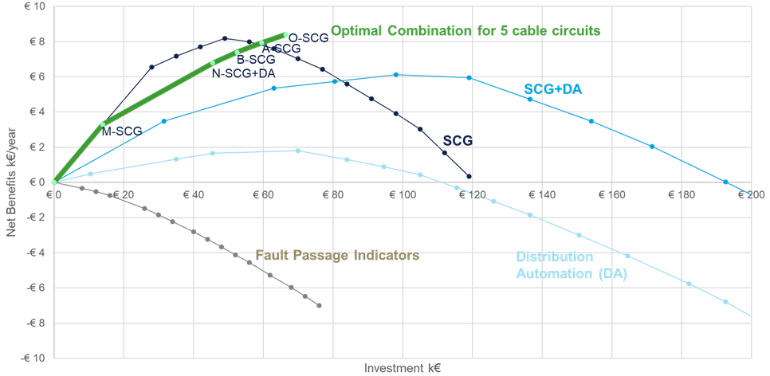

All 15 cable feeders of the substation under consideration were analyzed during the use of SCG, DA and FPI (including remote reading). In this analysis, the length of the cable circuit monitored by SCG was limited to 3 km due to the high ratio of paper insulated (PILC) cables. Furthermore, SCG and DA were not combined with FPI, as both technologies already encompass fault detection functionality. The overall result of the cost-benefit analysis showed that, out of the fifteen cable circuits, the five longest cable circuits with a large number of secondary substations (over 10) and the highest load (over 1 MW) had a positive cost-benefit result when SCG, in some cases in combination with DA technology, was used. Exhibit 1 shows the overall results of the cost-benefit analyses: in decreasing order, cable circuits M, N, B, A and O benefit from using SCG or a combination of SCG and DA. The use of FPIs has a negative cost-benefit result in all cable circuits.

Exhibit 1. Overall results of applying SCG, DA and FPI across a substation

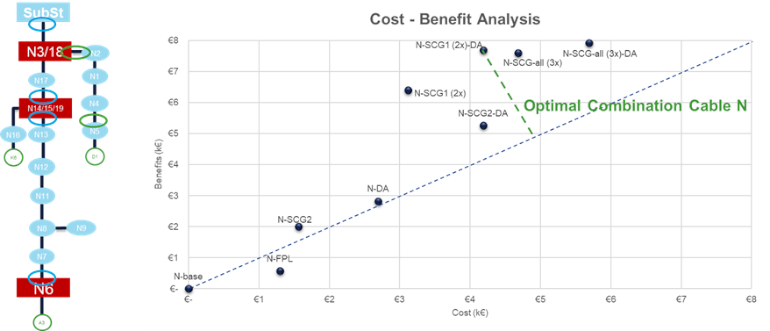

Exhibit 2 details the options for one of the 15 outgoing cable circuits, named N. The diagonal represents the break-even line between costs and benefits. The distance from this straight line is therefore decisive for its financial result. For cable circuit N, a combination of two SCG systems and the implementation of DA in three secondary substations provides the highest quality of supply. Installing this combination of digital technologies would also allow RNG to reduce the expected outage time of this specific cable circuit from 7.5 minutes to 0.7 minutes. The deployment of a third SCG system in the branch between N3 and N5 would reduce the outage time further to 0.5 minutes but would lead to a negative cost-benefit result.

Exhibit 2. Evaluation of all relevant combinations of digital technologies in cable N

To verify the results of the cost-benefit analysis, DNV also conducted a network reliability calculation using the NEPLAN® software. A grid model for the characteristic grid area was created with which load flow and reliability were calculated for the medium-voltage network of this substation. The results from these reliability calculations show that, like in the cost-benefit analysis, cable circuits M, N, B, A and O are the optimal target for the use of SCG.

If the suggested combined technologies are applied to all five cable circuits that benefit from digital technology the expected outage time (ASIDI) for the entire area covered by this substation will reduce from 3.8 minutes to 1.7 minutes (-55%). Based on this improvement, the investment required for these five cable circuits yield an annual return of more than 8%.

More information

Would you like to learn more on this cost-benefit model developed by DNV? A more detailed article was published in the German trade magazine Energiewirtschaft ew-Magazin 6/2022 | ew-Magazin (login required). This news article can also be downloaded as a pdf here.

Or get in touch with DNV’s Smart Cable Guard team to discuss how to decrease outage time on your power grid.