To build confidence amongst investors, governments, and stakeholders and thereby enable the rapid deployment of CCS, risks must be carefully managed. This requires the application of rigorous hazard management processes combined with an adequate understanding of the properties and behaviours of CO2 in the different parts of the CCS value chain.

DNV has a long history of supporting industry to meet the challenges involved in safely managing CCS projects. We have promoted and led multiple international research projects (e.g. CO2RISKMAN JIP, CO2PIPETRANS JIP, COOLTRANS JIP) to fill knowledge gaps for CO2 safety risk management. DNV shares its expertise with industry in the form of recommended practices and through its advisory and support services which cover the full CCS value chain.

Our services

DNV can support the industry through:

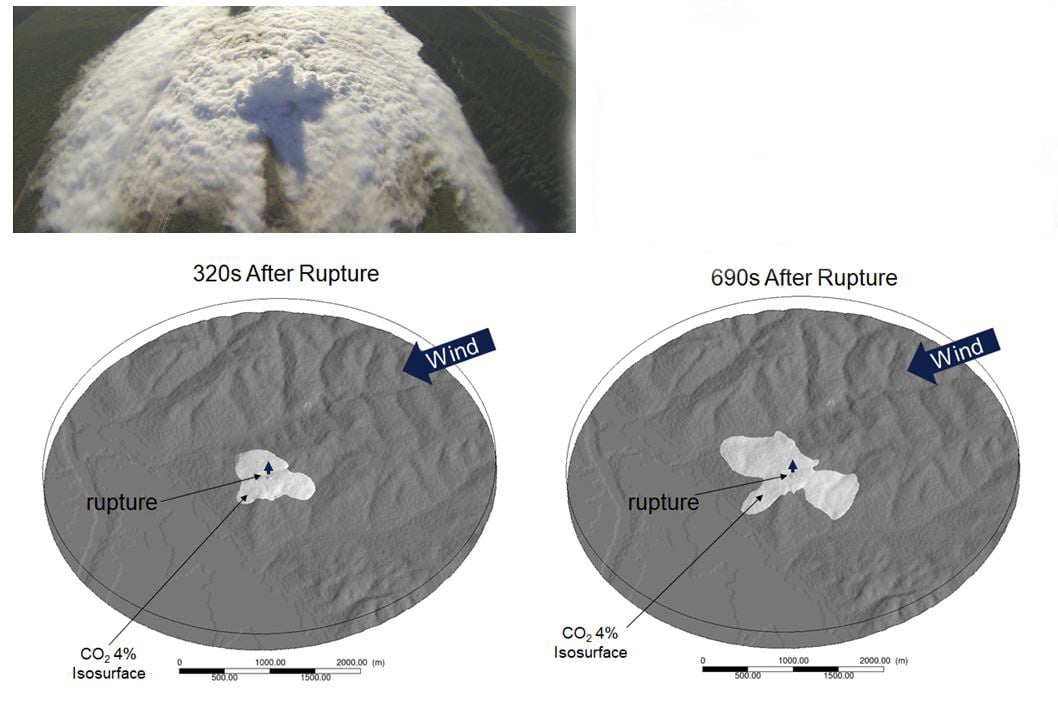

- CO2 dispersion modelling, using 3D Computational Fluid Dynamics (CFD), as well as simplified models, covering releases from process equipment, pipelines (buried and above ground), subsea equipment, releases on complex terrain, venting, presence of impurities etc.

- Quantitative and qualitative risk assessment (QRA, cold temperature risk, escape and evacuation assessment, SIL, HAZOP, HAZID, LOPA etc.) studies for the whole CCUS value chain, such as:

- Capture of CO2

- Transportation of CO2

- Storage of CO2

- CO2 gas detectors layout optimisation

- Modelling of cooling behaviour (potential embrittlement) of structures / equipment due to exposure to CO2 releases and assessment of mitigation measures.

- Risk-based technology qualification according to DNV Recommended Practice

- Full-scale testing of CO2 releases (gas and dense phase, buried and above ground pipelines, venting, fracture propagation, releases in confined spaces, releases from flanges, potential low temperatures on flange and bolts, mitigation by insulation, etc.) at DNV's Spadeadam Site.

- Regulatory support.

Test (above) and modelling (bottom, CFD) of a CO2 release from a buried pipeline on complex terrain.

Case study: HyNet North-West CCUS – Pipelines

ENI had defined a feasibility stage design for the transport and storage of captured CO2 via existing and new build infrastructure in the North-West of England and Wales. With the objective to consolidate the understanding of associated hazards, ENI asked DNV to include the consideration of topography in the risk assessment for the pipeline.

As a result, DNV conducted CFD modelling of loss of containment scenarios accounting for the topography in detail aiming at refining the pipeline Quantitative Risk Assessment (QRA). The CFD results were then used in the DNV software SAFETI (the industry standard for risk assessment). The potential of both tools (CFD and risk assessment) was thus exploited providing an enhanced risk picture.

The DNV study supported the design process as well as ENI in relation to discussions with the Regulator.