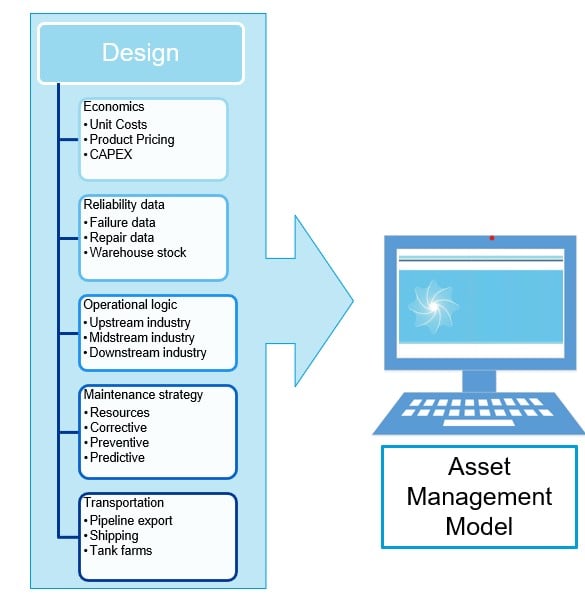

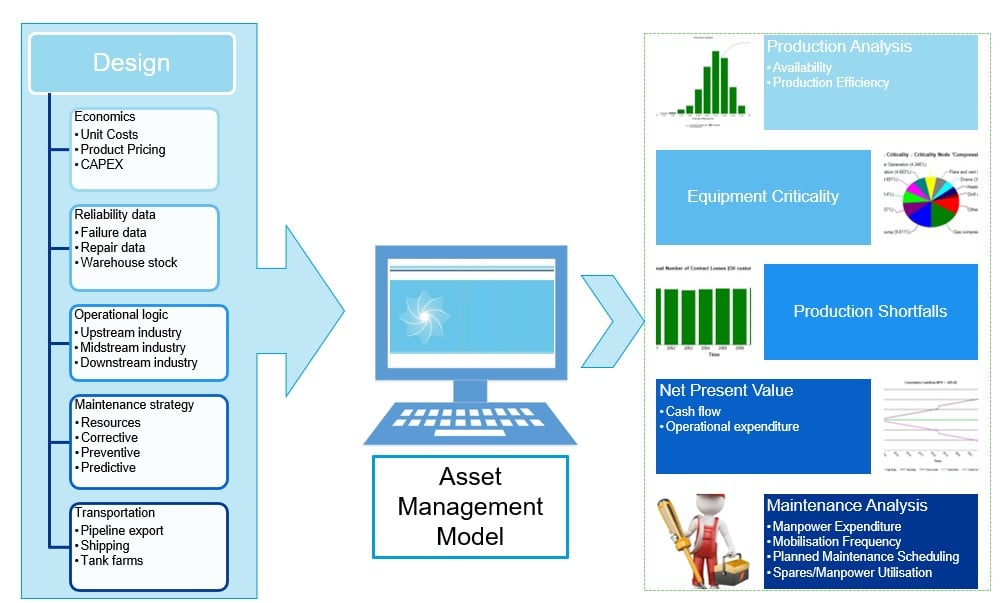

What is needed to perform a RAM Study?

Maros and Taro require some basic information to run a study. This article aims at answering: What is needed to perform a RAM Study?

Design basis

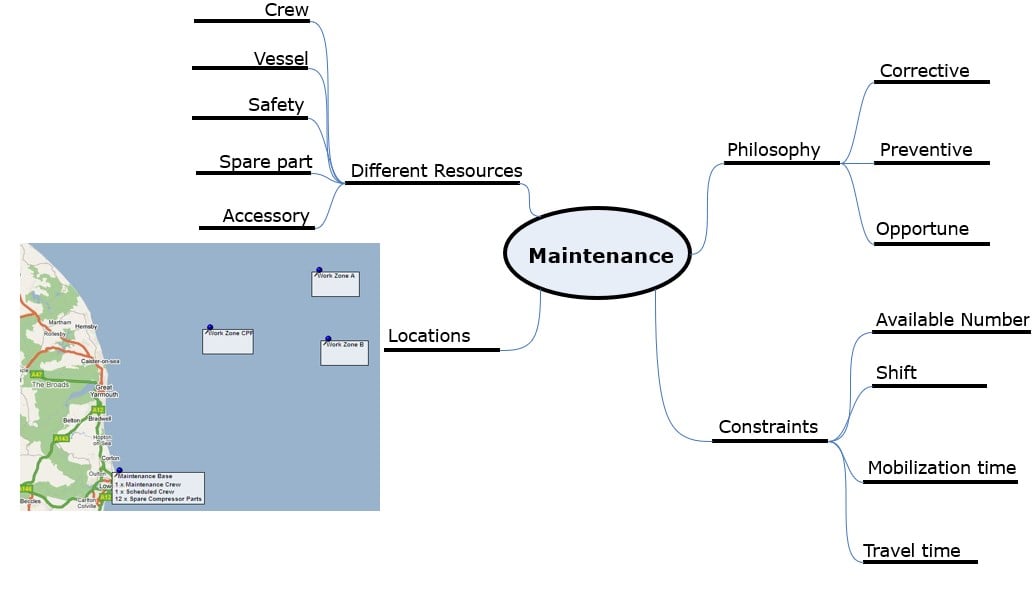

The first step of any project aiming at building a RAM model involves becoming familiar with the system design that you are about to convert into the digital twin. This might include looking into operations and maintenance strategies but let’s leave that discussion till later on.

The initial pieces of information required are:

- System Life:

- For design studies, this would be defined as the design life

- For studies during operations, it might refer to a specific period of time e.g. 5 years, the next business plan cycle.

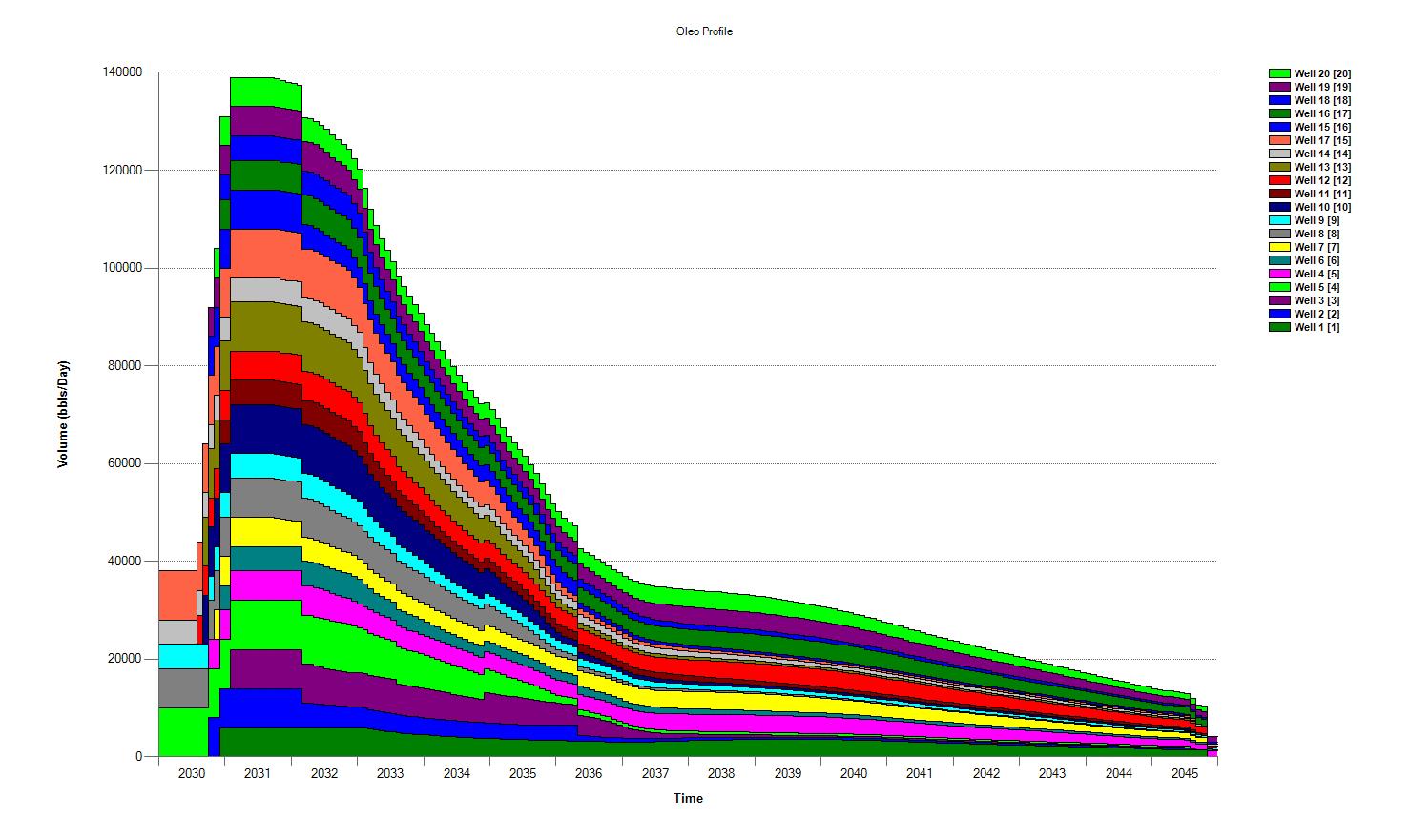

- Design capacity of the different units

- Equipment list: this data will vary depending on the study level.

- For the design phase, production-critical items are typically used

- For manning studies, non-production critical items would also be included to assess the delays related to maintenance logistics

A number of documents can be used to achieve the goal of the last bullet point. Amongst the most important documentation, I would refer to:

- Process Flow Diagrams (PFDs): A PFD is a diagram commonly used in engineering to indicate the general flow of plant processes and equipment.

- Process and Instrument Drawings (P&IDs): A P&ID includes more details than a PFD. It includes major and minor flows, control loops and instrumentation

These diagrams will be used to transform design information into a Block Flow Diagram (BFD) and Reliability Block Diagram (RBD). A Block Flow Diagram (BFD) defines the connectivity of nodes and focuses on the production aspects of the system e.g. flow rates and product mass balances. Each node within the network will require its own Reliability Block Diagrams (RBDs). These are used to identify the system’s components and their operating mode.

Once we know what equipment items to be included in the model, we start looking into collecting reliability data.