Smart or genius: How do you rate pipeline risk and integrity management?

A retrospective on pipeline risk and integrity management

Has the oil and gas pipeline industry learned from others?

O&G pipelines are the safest and most efficient way to transport natural gas and hydrocarbon liquids over long distances. However, how effective are your pipeline integrity and risk management processes and software tools that help keep them that way? Integral to this is capturing experience and lesson learnt from the past. Undoubtedly, learning from our own mistakes is smart. However, the genius among us learn from the mistakes of others. As an industry, has it demonstrated having embraced the broader learning from incidents across the oil and gas industry? So, genius or simply smart?

An event that changed the oil and gas industry

Piper Alpha memorial, Hazlehead Park, Aberdeen, Scotland

Firstly, let me take a step back in time. Earlier this summer I celebrated having been in the O&G industry for 30 years. On that day in 1988, how could I ever imagine what was about to unfold that week? Only 2 days later, 6th July 1988, a tragic event would change the industry forever. That event was of course the Piper Alpha disaster in the UK sector of the North Sea, which saw 167 people lose their lives. The darkest of moments for too many families, communities and for the industry. The haunting images remain of the inferno that took place just 120 miles North East of Aberdeen. Aberdeen had been my home for 8 years and a good many family, friends and peers had opted to work offshore.

The images and the “what could have been” thoughts were a profound awakening to individual and institutional behaviors. It fell upon everybody involved in the industry to strive toward ensuring such an incident never occurred again. Not least upon a Ph.D. graduate who had newly entered the industry.

What went wrong?

The ensuing investigation, presided over by Lord Cullen, revealed serious shortcomings in operations relating to safety, processes, communication, information availability and management of change. The findings led to many recommendations which found their way into UK health and safety standards. Additionally, they have formed the foundation of best practice in process safety, maintenance management and asset integrity management around the world.

So, have we learnt?

Back to my question. How well has the pipeline industry responded and embraced the lessons learnt from this and subsequent events? Generally, in my view, it has been patchy from a global pipeline industry perspective when assessed relative to other sectors of the O&G industry.

Pipeline industry reaction

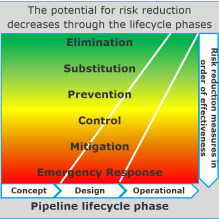

The first moves, in the 1970’s and 1980’s, were to improve pipeline reliability and safety by introducing construction and manufacturing standards. Added to this was a stronger focus upon selecting more effective and safer routing of the pipeline. I applaud this, because what we do from concept through construction provides the most powerful of the risk reduction options. Subsequently, in the 1990’s and early 2000’s along came a proliferation of regulations and guidelines.

High impact risk reduction occurs during the design and construction phases. Decisions here tie in 90% of lifetime costs.

These regulations mandated, or advocated best practice for, pipeline operators to manage the “integrity” of their pipeline. Of course, these are based upon risk management and oriented towards mitigation of the risk drivers, albeit in substantially different ways. The main contributors to the development of the fundamentals of integrity management have been industry bodies like ASME and API. Many consulting organizations have led the way in advocating best practice and in helping pipeline operators implement effective integrity plans. Among these are DNV providing innovation and leadership globally.

The aftermath of the San Bruno pipeline accident

Has the response been good enough?

Despite the Piper Alpha review, the extrapolation of lessons learnt did not get embraced in the pipeline sector as rapidly as would have been desired. Furthermore, it took “in my backyard ” onshore pipeline incidents in Europe and North America to break the inertia in the adoption of regulated integrity management. Arguably, 30 years on, the lessons learnt have not yet been fully embraced in the pipeline industry. Many, if not all, of the news headline making pipeline incidents in the past 20 years have had at their core the same category of issues that led to the Piper Alpha failure. Namely, inadequate processes, poor communication, limited information availability and inadequacy of management of change processes.

Industry regulators and best practice

The UK and Canada were among the first to respond in mid-1990’s. The US gas and liquids pipeline regulations followed in the early 2000’s and the European Union in the mid-2000’s. All of them have had significant revisions along the way but substantially remain the same. There are notable philosophical differences among them. First is the goal oriented approach putting the onus upon the pipeline operator to demonstrate having reduced risk to as low as reasonably practicable (ALARP). Secondly, there is the more prescriptive approach which explicitly sets out what must take place. More recently the largely prescriptive regulations in the United States have come under challenge from the regulator. One example, is the criticism towards the prevalence of index and relative risk models being used. The criticism is because these types of model have limited capability in assessing true risk levels or in identifying the most effective threat mitigation.

Pipelines – A global industry with common problems

The pipeline industry globally faces broadly the same set of problems. Of course, it is difficult to compare failure rates and impact across various regions due to variations in reporting criteria. However, the leading causes of failure are external interference, corrosion (external and internal) and material failure or construction defects. These have accounted for more than 75% of pipeline failures since 2010. Note that external interference, such as 3rd party excavation damage, is the prevalent threat in almost all regions. Noteworthy is that in Australia, which has an order of magnitude less failures than witnessed in Europe or the United States, interference damage alone accounts for more than 85% of incidents.

Pipeline digital solutions: Embracing the lessons learnt

We strive to deliver the best possible digital solutions that meet the deep rooted needs of the pipeline industry. To do so, we must not only embrace the lessons from the past, including those learnt from other industries, but we we must also anticipate changes and harness technological advancement to best advantage.

In a previous blog, I wrote about the principles behind our cloud enabled pipeline ecosystem product. Central to that is the objective to break down organizational and information silos. This, when combined with integrated engineering and data analytics, provides a robust platform for effective decision making. This directly addresses core issues from the industry lessons learnt discussed earlier in this post. Now, with the latest release of our risk and integrity management solution, Synergi Pipeline 8, we have taken this further. We have done so on by focusing upon three key areas:

- Supporting customer specific integrity management plans and the generation of detailed operational plans to deliver on the plan objectives.

- Enhancing the analysis capabilities by,

- Introducing a completely redesigned solution supporting inline inspection data assessment

- Enabling the development and use of probabilistic risk models. These models now becomes our standard recommendation for risk assessment solutions

- Enshrining information integrity into processes. An example is in how we mange the alignment, storage and analysis of multi-vendor inline inspection data. This includes support for the recommendations of API 1163 and the Pipeline operators Forum’s 2016 version of their “Specifications and requirements for in-line inspection of pipelines”

In subsequent posts I will take a closer look at what makes effective integrity and risk management digital solutions.

Author: tom Gilmour

9/28/2018 2:13:37 PM