How artificial intelligence can provide fast and reliable turbine interaction modelling for the biggest wind farms

Offshore wind farm development faces a “big” problem. As tomorrow’s wind farms cluster into groups of many hundreds of turbines they become so big that they have significant influence on the atmospheric boundary layer, complicating the flow dynamics and reducing available energy through wake and blockage losses.

Engineering wake models have been available in wind farm design software, such as WindFarmer, for 25 years and used reliably to design productive wind farm layouts. However, there is more modelling uncertainty for the new, bigger, wind farm scales of tomorrow, and more money at stake. Fast engineering wake modelling approaches have been validated and tuned against the biggest wind farms operating today, but not against the planned mega-clusters offshore, or the GW scale onshore wind farms of tomorrow. How can we simulate tomorrow’s wind farms with confidence?

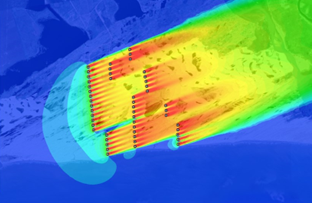

There is another way. DNV’s high-fidelity Reynolds-Averaged Navier-Stokes Computational Fluid Dynamics (RANS CFD) model simulates the interactions between the wind farm and atmosphere from first principles, making fewer engineering assumptions. We expect this approach to generalise much better than engineering models when applied to larger wind farm scales never built before.

Tackling complex wind flows in large wind farm clusters with WRF-to-CFD

DNV recently upgraded its RANS CFD approach to use output from the Weather Research and Forecasting (WRF) mesoscale model to improve simulations of the complex interaction between wind farm and atmosphere. This WRF-to-CFD approach has been validated against measurements of internal wakes, external wakes, and blockage effects at many wind farms, including those reported on in [1]. The validation shows that WRF-to-CFD empowers DNV to minimize uncertainty in wake and blockage predictions, especially for large wind farms.

Running a high-fidelity WRF-to-CFD analysis at least once during your project development process is advisable for many projects, especially those with higher wake losses (and consequently greater uncertainty in energy production forecasts). We may expect further benefits from WRF-to-CFD at onshore sites with complex terrain where the straightforward addition of wakes with ambient wind flows assumed by engineering models breaks down. However, these detailed WRF-to-RANS CFD simulations are computationally expensive and require significant hours of supercomputer simulation time. As a result, assessing the hundreds or thousands of layouts typically considered during wind farm design becomes impractical using this approach. While engineering models are efficient and valuable for layout optimization, they do not capture critical physical effects at larger wind farm scales.

CFD.ML provides a faster solution

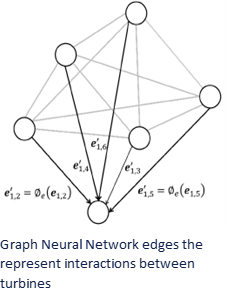

CFD.ML offers an alternative solution for fast simulation of wakes and blockage, without such engineering simplifications. CFD.ML is a machine learning surrogate for DNV’s high-fidelity RANS CFD solution [2]. It’s Graph-Neural-Network “brain” is trained to emulate the turbine interaction loss factors predicted by DNV CFD, encoding production patterns associated with both wake and blockage effects. As DNV analysts model more wind farms at high fidelity, CFD.ML learns from this experience. What’s more, the CFD.ML is being trained on the largest future wind farms that won’t be built for a few years, so it’s ahead of the curve. Since 2020 DNV has used CFD.ML as an interpolator of the high-fidelity CFD model, allowing us to simulate a reduced number of wind directions and yet fully capture the wake effect variation by wind direction for a project. Now, with more experience and training we can explore using CFD.ML as a stand-alone model.

Blockage corrections considering the wind rose and layout

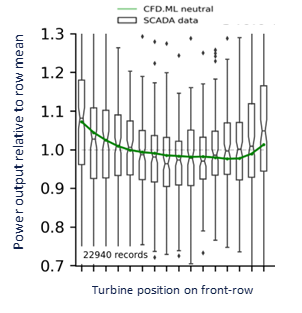

By post-processing CFD.ML results we can estimate the blockage corrections, which should be applied to a wakes-only model. We expect CFD.ML to be more reliable than the current DNV BEET Blockage Correction model in accuracy as it understands the wind farm layout and predicts directional variation in blockage impacts, important when your farm or wind rose is far from non-uniformly distributed by wind direction. In a SCADA validation study [3], comparing modelled and measured power time series at offshore projects, we have seen CFD.ML generating better predictions of the pattern of production across the wind farm relative to other engineering models.

The future of wake modelling will be boundary layer intelligent

In 2023 however, testing of a CFD.ML model trained on CFD simulations of a neutral boundary showed that long range, offshore cluster to cluster wakes were greatly underpredicted, but an alternative CFD.ML version including some training on a CFD simulations of wind farms in a stable boundary layer performed much better [4]. To simulate wakes reliably at the larger scales, and recognising site specific variations in conditions, we recently upgraded CFD.ML to be a multi-stability model by retraining the core Graph Neural Network to capture a much wider set of atmospheric boundary layer inputs used as boundary condition parameters in our high fidelity WRF-to-CFD simulations. These extra parameters improved the new multi-stability CFD.ML model’s skill at replicating WRF-to-CFD predictions at sites not included in the training process.

CFD.ML offers a new hope for enhanced and expedited turbine interaction modelling, unencumbered by the engineering assumptions typically necessary for rapid models. When it comes to correcting for blockage effects, absent from wake models, transitioning to CFD.ML represents a small yet unequivocally advantageous step. Established blockage correction methods use unproven potential flow models or rely on simplistic curve fitting to RANS CFD results. In the context of wake modelling, CFD.ML today may also identify scenarios where further high-fidelity modelling could be beneficial, especially when results deviate from predictions by established models. Our aspiration with CFD.ML is to incorporate modelling benefits—typically associated with supercomputer-intensive high-fidelity simulations—into WindFarmer, while maintaining run times conducive to layout optimization. If we educate CFD.ML well, we may rely on it for direct estimates of the full turbine interaction effect, reducing uncertainty at the largest wind farm scales.

[1] Christiane Montavon, 2023, WESC, Glasgow

[2] James Bleeg 2020 J.Phys.: Conf.Ser. 1618 062054

[3] T Levick et al 2022 J. Phys.: Conf. Ser. 2257 012010

[4] Mitraszewski, WindEurope technical workshop, Lyon

3/18/2024 7:02:00 PM