Strength and fatigue service – rotating machinery

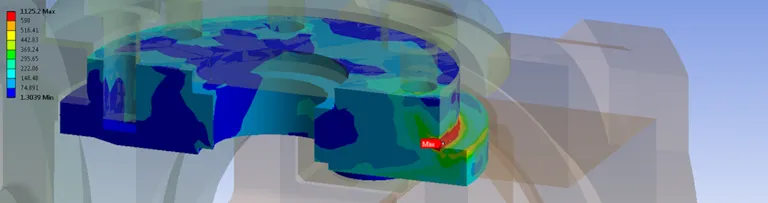

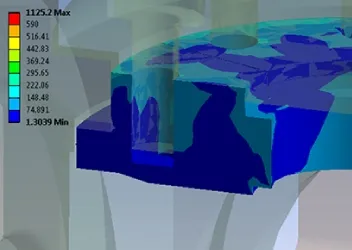

For structures with a complex geometry, we use FEA to provide more reliable results, to optimize design and reduce testing.

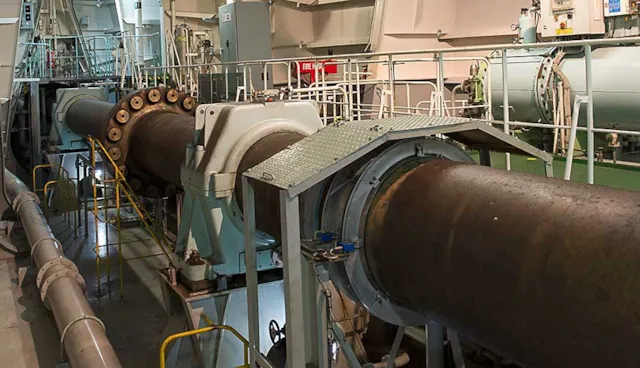

Ship machinery is subject to static and dynamic, internal and external forces. Costly testing and verification, complex geometries, design improvements and troubleshooting demands the necessary expertise and tools.

Our experience has shown that Finite Element Analysis (FEA) is the best tool for predicting static and dynamic responses, such as stresses, strains and displacements, in complex structures. These include ship machinery parts, such as propellers, gearing wheels, couplings, shafts and turbo machinery, that are subject to many wearing and potentially damaging forces.

That’s why we use FEA for:

- Design and design optimization

- Design verification

- Troubleshooting and damage investigation

Our experts utilize a diverse range of advanced FEA software such as ANSYS, IDEAS, ABAQUS and SESAM to evaluate strength, vibrations or fatigue. Thanks to our extensive knowledge base, we know which calculations to perform and how to interpret these for a holistic and reliable solution.

In addition, physical tests performed in our own metallurgical laboratory can be carried out. These tests can verify the material data and investigate the root cause of failure modes.

Your benefits of using DNV for strength and fatigue analysis on complex machinery:

- Reduce cost and maintenance

- Results built on our multidisplinary technical knowledge and experience

- Flexilbility – book our services as a complete package or separately

- Overview of the trouble areas and reliable recommendations from experts