Turbulence ahead: clashing trajectories between wind turbine design and siting and life extension

The commercial and technical trends in wind energy development in North America have been evolving at a rapid pace for the last several decades. Two recent trends, wind turbine design and siting practices, are currently heading for conflict, with impending impacts that limit opportunities for life extension and partial repowering.

Historically, excess margins against long term failure of major structural components (e.g. blades, hubs, shafts, bedplate, tower) have been present due to the use of more conservative approaches in the design standards and conservative approximations made in design calculations. However, as computing capabilities and cost competitiveness increases, turbine designers and project developers are using methods that, while allowed by standards and engineering reasoning, results in a loss of the conservatism that has historically been in place. At the same time, project developers’ and owners’ expectations for turbine operating life have been increasing, having observed early generation wind farms operating into life extension, and assume that history will repeat itself.

However, methods have changed and historical experience cannot be carried forward, setting up a potential clash between expectations and actual outcomes. In this case, there is higher uncertainty on whether the desired outcome (longer turbine useful operational life) can be achieved. Unfortunately, unlike digital platforms that can make a change to their products/services and obtain results from millions of users nearly instantaneously, the impact of methodology changes to turbine design and siting can take years and even decades to become apparent. As a result, predicting the long-term fatigue reliability of the major structural components based on these methodology changes is difficult.

Blade design is a key aspect of the observed trends, which is covered in detail in DNV’s white paper “DNV Perspective on the Challenges of Blade Durability.”

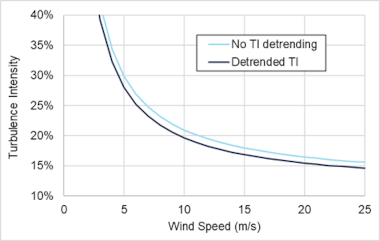

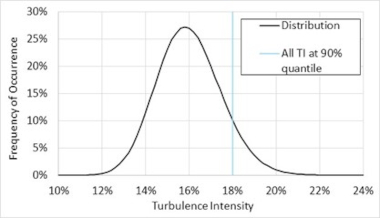

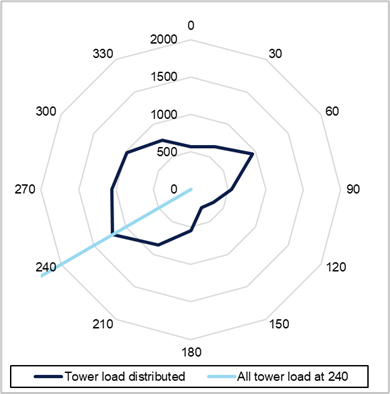

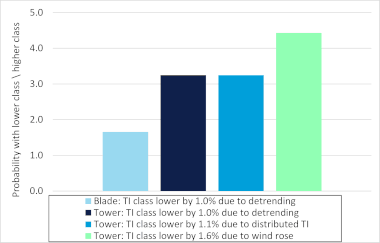

Some perspective can be gained by looking at these methodology changes via thought experiment and high-level calculations. Take three examples: detrending of the measured turbulence intensity at a site (Figure 12), use of a full distribution of turbulence for design or siting load calculations instead of only the 90% quantile (Figure 13), and spreading the tower loading around the wind rose instead of assuming it all occurs from one wind direction (Figure 14). These three methods are allowed by the design standards but have only recently come into widespread use. It should be noted that in these cases tools and methodologies are reviewed and approved by certification agents such as DNV with reference to appropriate standards. DNV encourages this as best practice to give the most confidence that these methods are applied appropriately and accurately. However, in each case, the change allows the use of a turbine with lower environmental class conditions than would historically been selected for a given wind site. The difference in the fatigue life and failure probabilities between the higher- and lower-class turbines when using the historical approach can then be calculated to quantify the impact of these changes.

|  |

| Figure 12 TI detrending compared to historical methods | Figure 13 TI Distribution compared to historical methods |

Figure 14 Tower distributed loads (in hours) compared to assuming all loads occur at the most loaded wind direction

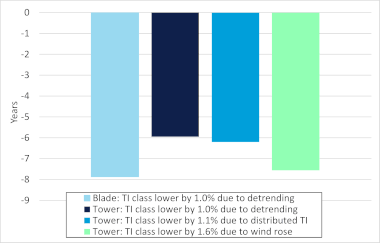

DNV uses a suite of in-house tools to estimate site fatigue loading calculations relative to certified design conditions, which can also feed into a tool that assesses structural reliability. The latter considers the load and strength uncertainties along with the safety factors required by the standards to arrive at an estimate of reliability, or inversely, probability of failure. The three aforementioned methods were used to determine a potential allowable reduction in turbulence class which was then evaluated for fatigue life and failure probability using the more conservative historical methods (Figure 15 and Figure 16). These results are approximate and meant to be illustrative; the impacts from unique real-world scenarios may vary considerably.

|  |

| Figure 15 Reduction in the P50 life in year 20 | Figure 16 Change (ratio) in fatigue failure probability in year 20 |

The impact of the more refined and less conservative methods is not trivial in terms of reduction in fatigue life and reliability. The opportunities for life extension appear robust in part because of the industry’s experience with turbines designed and sited using historical methods. However, new, more aggressively designed turbines and sited projects may not be economically feasible for life extension. While there are benefits to be gained by improving methodologies, the potential risks should be considered carefully. To mitigate these risks, DNV recommends owners and developers take the following into account:

- Obtain good quality, extensive, and comprehensive site conditions characterization

- Design a robust site measurement campaign to reduce uncertainty in siting

- Review the approach the OEM has used to calculate turbulence intensity

- Carefully consider changes in siting and design methods within a wholistic risk assessment. In DNV”s opinion, subject matter expertise in development and use of design and siting methods and tools are crucial to keeping the balance between costs and conservatism. In this context technical cooperation between all parties, including third party review is highly recommended to minimize risks.

- Maintain the required quality in manufacturing and installation due to the reductions in conservatism

- Perform engineering checks on any changes to turbine configuration or operation that may result in loading impacts, such as power curve changes

- Perform frequent, high-quality inspections on highly loaded components

- Conduct or update a site suitability and life extension analysis prior to financial commitments

- When conducting an LCOE analysis, ensure higher O&M costs are included when a site is aggressively sited.

5/17/2023 3:00:00 PM