SIMFAT: SIMultaneous load processes in FATigue estimates

Joint industry project

DNV propose to launch a joint industry project for how to treat simultaneous load processes in fatigue estimates.

Industry need

Offshore structures are subjected to fatigue loading from several simultaneous load processes. Wind, current, and waves induce floater motions and apply direct loads on the offshore structure. Such different load processes are often treated separately, while the aim is to find the combined fatigue life of the structure. The interaction of two or more loading processes complicates the assessment of fatigue damage in offshore structures, and industry practice is generally lacking in how to include the effects accurately.

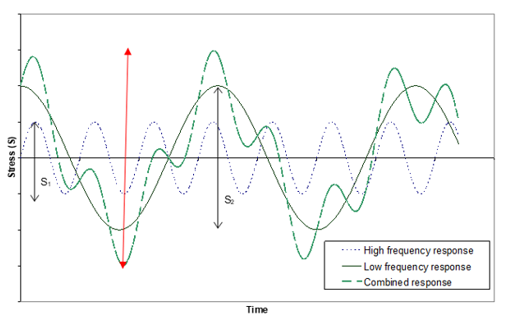

Figure 1 Illustration of two simultaneous load responses.

There are numerous examples across the industry that illustrate the challenges posed by combined loading processes. In the case of riser systems, wave loading is generally present, currents may trigger vortex-induced vibrations (VIV), while internal flow may result in slugging. Additional effects, such as heave-induced VIV and low-frequency vortex-induced motions (VIM), can also contribute to fatigue loading. Fatigue loading on flare towers and bridge structures is significantly influenced by both wind- and wave-induced processes, which are typically evaluated separately in standard assessments. Mooring balconies on spread-moored FPSOs experience combined fatigue loads from the dynamic response of the mooring system and local wave impacts. Similarly, floating offshore wind structures are subjected to complex fatigue loading from floater motions, wind forces, and wave impacts. Other examples include riser balconies on floating structures, where vessel motions and direct riser loads act together, and SPAR structures, where slow-varying pitch and roll responses interact with higher-frequency wave induced motions. These scenarios demonstrate the wide-ranging complexity of addressing simultaneous load processes in fatigue assessments.

Despite their critical role in structural integrity, accounting for these simultaneous load processes in a unified analysis is generally deemed too complex and time-consuming, particularly during early-phase design stages. Moreover, industry-standard tools often lack the necessary functionality. Simplified methods outlined in design codes tend to be overly conservative, and design practices across the industry vary significantly. This inconsistency leads to substantial differences in how fatigue from simultaneous load processes is estimated. DNV considers the establishment of a consolidated approach for addressing simultaneous load processes in fatigue evaluations to be beneficial for the industry.

Simplified fatigue methods for simultaneous load processes, with known uncertainty, is not available in the industry. As of today, fatigue from simultaneous load processes is addressed by several uncertain methods. Methods in use include known unconservative methods - such as the ‘linear sum’, and methods with generally unknown bias - such as the ‘quadratic sum’ applied on long-term fatigue damage[1] and the ‘simplified formula’ from DNV-RP-C203[2].

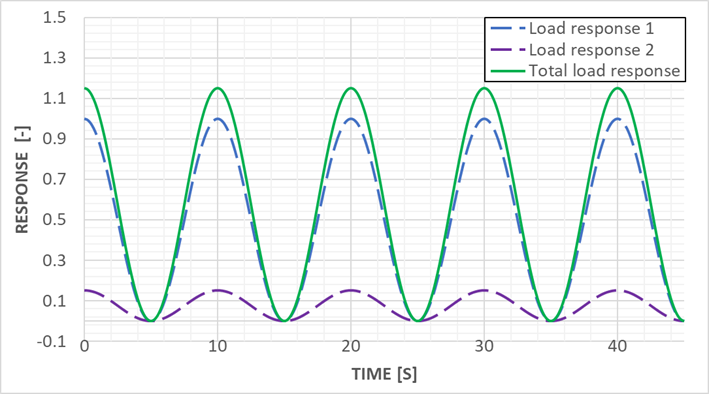

To illustrate the error by applying ‘linear sum’ of two simultaneous load processes, we can assume two load responses in phase. Please see Figure 2 for illustrations of the load responses. The first load gives a normalized response range of 1 and the second load gives a normalized response range of 0.15. The total load response will cause a fatigue damage. If the linear summation approach is used, the fatigue damage is calculated independently from each load response and summed afterwards, causing a fatigue damage. The total fatigue damage is approximately twice the damaged calculated by linear summation. This shows that linear sum highly underestimates the fatigue damage.

Figure 2 Illustration of the response from two simultaneous load processes.

Pilot study

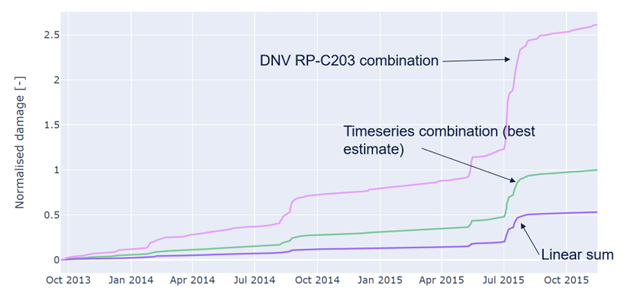

A pilot study has been conducted by DNV in cooperation with Equinor, focusing on deep-water steel-lazy-wave risers (SLWR’s), see reference[3]. This study assessed the fatigue amplification due to simultaneous fatigue from waves and VIV, and from waves and slugging. The VIV and waves result from the published paper are included in Figure 3.

More work has been performed in the pilot study which at present is unpublished. The JIP will build on the experience and tools developed in the pilot study, where the main developments relevant for the JIP include:

- Studies of methods applying spectral moments for describing stress processes and calculating combined damage.

- Preliminary assessment of effects due to wide-bandedness, non-Gaussianity, and including three simultaneous processes.

- Establishing tools for numerical simulations of multiple stress processes with varying characteristics, based on synthetic time series generated from stress spectra.

- Identifying bias for total fatigue damage from different stress spectra combinations using simulations.

Some of these topics may be included in future publications.

Figure 3 Fatigue damage from wave and VIV loads.

Project goal

The overall project goal is to consolidate a common design methodology accounting for simultaneous load processes. The main goal is to cover 2 simultaneous processes, with ambition to cover 3 or more processes in the final methodology. This includes requirements for doing simultaneous fatigue assessments from a design basis perspective, recommendations for how to do design with a conservative simplified approach, and how to do design using more advanced methods. The exact design format for the simplified approach is not worked out fully, but at present the idea is to use linear sum and introduce a separate bias factor accounting for the stress amplification due to simultaneous loading.

The work will also address the methodology in use today (linear sum, quadratic sum, DNV-RP-C203 method) and see when they are applicable.

Note that fatigue from simultaneous load processes is a generic problem with applicability beyond risers and cables. Methodology developed should be relevant for all structures but will only be tested for cases relevant to risers and cables. The aim is to establish a practical “good enough” approach, enabling separate analysis of different load processes in a standard way throughout the industry. Guidelines for more advanced analysis will also be included.

On a high level, the following work packages are proposed:

- WP1: Design methodology short-term conditions

- WP2: Design methodology for long-term environment

- Including requirements for design basis and metocean specification

- WP3: Case studies

- WP4: Assessment of load effect analysis methodology

- WP5: Guideline development

Benefits

By participating in the JIP, members can expect the following benefits:

- Clear understanding of governing parameters for simultaneous fatigue from different processes.

- A framework covering the process from writing design basis and metocean specifications to recommendations for performing analyses considering simultaneous fatigue from different processes.

- Possibility to influence the recommended design methodology for fatigue design.

- Early-access to findings from the project.

Project overview and execution plan

Schedule

The current scope is estimated to be 18 months, depending on feedback from participants. Kick-off is scheduled for the 1st quarter of 2025.

Deliverables

The main deliverable is a guideline with findings from activities listed above. Technical reports from each activity will also be made. It is intended that a synthesis of the guideline will be made publicly available, whereas some results will only be made available to JIP participants. Learnings from all the studies conducted will be shared with the JIP participants. The results may lead to updates of the DNV design codes.

Participants

We aim for a balanced group of companies within the energy sector. DNV will be responsible for managing the project.

Fee structure

The cost, schedule and more detailed information will follow. The final scope and budget will depend on number of participants and on the outcome of the detailed scoping.