Guidelines on materials qualification for underground hydrogen storage

Joint industry project

A joint industry project to develop guidelines on the appropriate use of fitness for purpose methods to design and use materials in H2 storage applications.

Our joint industry project (JIP) on "Guidelines on materials qualification for underground hydrogen storage" aims to pioneer this change. This initiative focuses on understanding and optimizing the use of existing underground storage infrastructures for hydrogen, a crucial step in integrating H2 into our energy mix.

Challenge

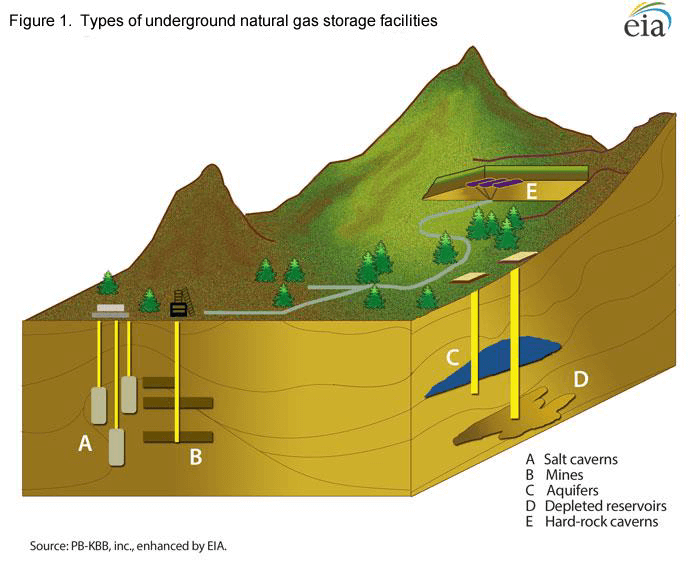

The central challenge lies in adapting current storage infrastructures, primarily designed for natural gas, for hydrogen storage. Our existing infrastructure must evolve to handle the unique properties of hydrogen, particularly in terms of material performance and durability. The primary concern is understanding the impact of high-pressure hydrogen on materials and ensuring their suitability and safety for long-term hydrogen storage.

Objective

Our main goal is to develop comprehensive guidelines for selecting and using materials suitable for hydrogen storage applications. We aim to:

- Analyze the effects of loading modes on material fracture properties

- Understand the influence of gas chemistry and temperature on these properties

- Compare the material performance in hydrogen environments to that in aqueous environments, facilitating a seamless transition from traditional energy storage methods to hydrogen-based solutions.

Approach

Our approach encompasses a series of structured tasks and studies:

Task 1: Literature review and matrix development - Compiling existing knowledge and identifying gaps in the current understanding of material performance in hydrogen storage.

Task 2: Gas chemistry and temperature effects - Investigating how the composition of hydrogen and temperature variations influence material integrity.

Task 3: Loading modes impact - Assessing how different loading scenarios affect the fracture behavior of materials in hydrogen environments.

Task 4: Comparative analysis - Evaluating material performance in both hydrogen and seawater under cathodic protection, providing a broad perspective on material suitability.

This JIP stands at the forefront of enabling a greener future by ensuring the safe, efficient, and effective use of underground storage for hydrogen. By understanding and overcoming the challenges associated with material performance in hydrogen environments, we pave the way for a more sustainable and cleaner energy landscape. Join us in this exciting journey towards a hydrogen-powered future.

Benefits

It is expected the JIP will bring the following benefits to the members:

- Information to understand the impact of high pressure H2 on the fracture behaviour of various materials used in storage applications

- Understanding the influence of minor impurities and temperature on the fracture behaviour of materials in high pressure H2

- Understanding if the materials performance based on behaviour in seawater reflect their performance in gaseous hydrogen conditions.

Project details

It is expected the scope of the JIP can be delivered at a cost of kUSD 300 with five members participating (kUSD 60 per member). It is planned to execute this JIP in a duration of 18 to 24 months after commencing the testing.