Establishing flow meter traceability along the CO2 value chain

Joint Industry Project

DNV takes the lead in CO2 flow meter qualification

Challenge

With decarbonization ambitions moving forward, the transport of CO2 is becoming increasingly important to facilitate carbon capture, utilization, and storage (CCUS). As well as for natural gas systems, accurate measurement and subsequent billing for CCUS is required to show compliance with national and international emissions-reduction regulations, like the EU Emissions Trading System.

To enable flow metering performance assessments and qualification, test facilities are required that can operate within the demanded operational ranges and have a proven traceability to international standards. These facilities do not exist. DNV is leading a joint industry project (JIP) that brings together equipment suppliers and large TSO’s and E&P’s to target this industry need.

Objective

The JIP aims at building the world-first proven reference network of facilities for testing and calibration of flow meter technology along the entire CO2 value chain; from high-pressure dense phase well injection to low-temperature liquid shipping. These extremely challenging field conditions force DNV and the stakeholders to jointly explore the unknown territory for reference- and metering systems.

Approach

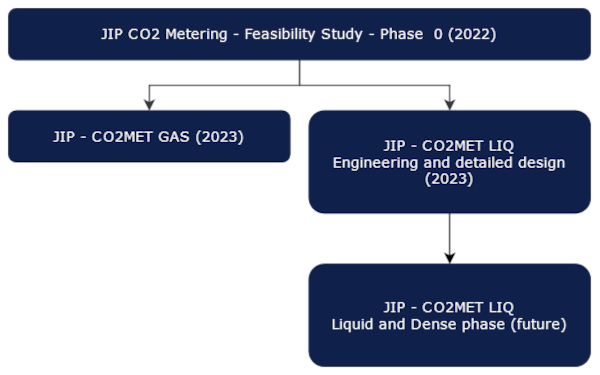

Due to the broad range of applications, the JIP structure will cover the application areas in different steps. An overview of the different projects is provided in the figure below.

- Feasibility study for CO2 flow metering calibration facilities

- CO2MET GAS: Calibration and testing in gas phase at pressures ranging between 10 and 40 bar at temperatures between -40°C and 30°C.

- CO2MET LIQ, Engineering and detail design of a facility able to test and calibrate in liquid/dense phase at pressure ranging between 7 and 150 bar at temperatures between -40°C and 30°C and supercritical phase at pressure ranging between 90 and 150 bar at temperatures between 30°C and 50°C.

- CO2MET LIQ, Liquid and Dense phase. Calibration and testing at liquid/dense/supercritical phase conditions.

A feasibility study for CO2 flow metering calibration facilities has been executed in 2022. Each phase is based on the knowledge generated in the preceding phases and will have a new contract where interested parties can join.

Project status

- Feasibility study has been completed on May 1st 2022.

- JIP CO2 MET Gas is ongoing. First performance tests at ambient conditioned completed in 2023. Expected project completion in Q1 2024.

- JIP CO2 MET LIQ, engineering and detail design will start Q1 2024. Project is open for new parties to join.

- JIP CO2 MET LIQ, construction and commissioning of a new facility is depending on previous project result.