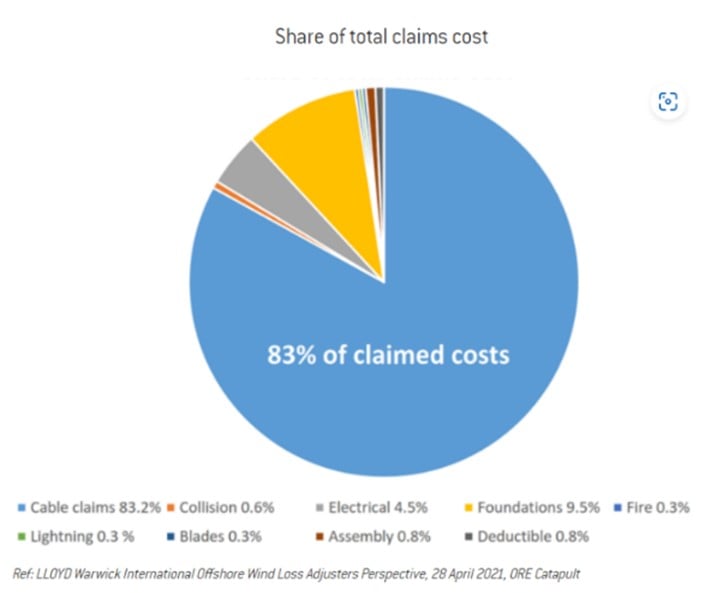

80% of insurance claims in offshore wind are related to subsea cable failures – How can the industry manage these risks?

As developers embark on the ambitious task of harnessing wind energy in open seas, they encounter a unique set of challenges, particularly associated with subsea power cables. Although subsea power cables are not new technology, the scale of offshore wind connections, particularly the large number of cable entries at each foundation, and the interface design required, introduces unique challenges previously unseen by the subsea cable industry.

According to Lloyd Warwick, an international specialist loss adjusting and claim management company, around 83% of all offshore wind related financial losses and insurance claims are attributed to power cable failures. Lloyd Warwick further reported that, with an average downtime of 40 days and 60 days for array and export cable repairs, the average combined losses (repair and loss of generation) ranges between $1.2m-$12m for array cables and $10m-$30m for export cables.

According to Lloyd Warwick, an international specialist loss adjusting and claim management company, around 83% of all offshore wind related financial losses and insurance claims are attributed to power cable failures. Lloyd Warwick further reported that, with an average downtime of 40 days and 60 days for array and export cable repairs, the average combined losses (repair and loss of generation) ranges between $1.2m-$12m for array cables and $10m-$30m for export cables.

So why do subsea power cables and cable protection systems fail and how can the risks be minimized? In this blog post, we will explore the challenges faced by developers in dealing with offshore wind cables and delve into the role that industry standards and certification plays in overcoming these obstacles.

Failure through poor interface design management

There are several reasons why subsea power cables fail, but there is not a public database from which root cause analyses and lessons learned could be drawn from a global scale. We further note that the subsea cable asset has historically not been subject to third party verification or certification services like those required for offshore wind turbine generators (WTGs) and Offshore Substations (OSS). However, we do note that there are emerging markets which do require project certification of the subsea cables, like Taiwan, USA and Poland. Based on DNV’s experience of certifying subsea cables in these markets, we have found that many of the publicly known subsea cable failures in the last years are the result of poor interface design management together with insufficient design for the actual site conditions.

Our observations may not be surprising if we look at the prevailing project setups and contracting principles for offshore wind subsea power cables. The current practice is to partition the design responsibilities between several parties, i.e. designers, consultants, suppliers, and contractors, and to utilize “rely upon” frameworks in which there is not an overall responsible design party. This is not to say that a single designer is required, but rather that these organizations will require careful planning of the design responsibilities and, most importantly, the development of a coherent design basis which covers the subsea power cable as a complete asset.

Introduce well-defined design requirements and standardize responsibilities

The good news is that there are already similar learnings and experiences with other offshore assets which can serve as a template to reduce subsea cable failures. We could look to offshore oil and gas and find technical solutions from our experience with umbilical and risers (a practice that is becoming more common), but there is a simpler solution already within offshore wind which can be implemented much more quickly. If we look at the design of offshore wind turbines and their support structures, this is another asset with a significant split between design responsibilities, but due to standardization, it is a design split that is well managed with significantly less mismanagement of interface design. This is primarily due to the very well-established process for developing a combined Design Basis between the project owner and the WTG supplier and the foundation designer. By following this approach and standardizing a well-defined Design Basis, including the site conditions, this will ensure that subsea power cables are designed as an asset rather than an individual component, significantly reducing the risks of failure due to design.

The role of standards and Project Certification

As recently highlighted by RECHARGE News, the cost of insuring Offshore Wind has “doubled” and although it is not entirely due to subsea power cables, they play a significant role in this new reality. To combat this, insurance brokers and providers point to the role that independent third party testimony, such as Project Certification, can play in to bring down the cost of insurance, and in some cases, even unlocking the availability of insurance policies.

Certification bodies like DNV are instilling confidence in investors, operators, and regulatory authorities by ensuring that offshore wind cables meet the highest standards of quality and reliability and that they are being designed with respect to the actual site-specific conditions.

There is a need for better standardization, both at a technical component level, but also at a project level. DNV is an active member in IEC, ISO, CIGRÉ, and other technical committees and working groups, but we are also maintaining and publishing our own standards. A prerequisite for effective standardization is to first understand the root cause of cable failures. Although there is only a limited amount of public information regarding known subsea cable failures, DNV’s insight as the leading certification body for offshore wind helps to supplement this information.

Further, industry collaboration and knowledge sharing via Joint Industry Projects (JIPs) provides significant opportunity in mitigating risks. DNV is currently leading two in which subsea power cables for offshore wind are included, Floating Wind Reliability JIP and Floating Offshore Wind Substations JIP. Lessons learned and experience from the industry needs to be collected, evaluated and translated into requirements documented in globally accepted certification standards.

DNV’s standard DNV-ST-0359 specifies the requirements to subsea power cable installations during all phases of a subsea power cable project with a focus on evaluation of renewable energy applications in shallow water including its landfall. First published in 2016, DNV-ST-0359 has served as a technical roadmap to the industry on how to design subsea power cables as an asset across all phases of its lifecycle, by highlighting the well-established electro-technical standards currently existing in the industry, but also by introducing additional mechanical design requirements previously missed within the standards landscape.

This standard is currently being updated to better map the current standards landscape regarding subsea power cables, but also to highlight the need for an integrated and site-specific design basis. This effort is anticipated to be completed in summer of 2024, but given the significant challenges facing the industry, a larger update is already being planning to incorporate the learnings from the above mentioned JIPs.

Please contact us to learn more about risk mitigation for subsea power cables in offshore wind projects.