Switching safely to low-GHG fuels and technologies

As the maritime industry shifts towards low-GHG fuels, ensuring safety during this transition is paramount. This article highlights the critical measures and considerations necessary for a safe and effective switch to low-carbon fuels and technologies.

Orderbooks are increasingly filled with LNG and methanol fuelled vessels as well as first ammonia ones, as shipowners respond to current emissions regulations and aim to lower carbon intensity in the near term. However, with the IMO targeting net-zero greenhouse gas emissions by 2050, both LNG and methanol derived from fossil sources are expected to serve primarily as transitional fuels, requiring a further shift to low or zero GHG alternatives. These could either be carbon-based versions of current fuels that are net-zero from a lifecycle perspective, such as biofuels or electrofuels, the use of onboard carbon capture, or a switch to zero-carbon fuels like hydrogen or ammonia.

Preparing for future fuel switches and their risks

To support this transition, it is essential that considerations for future fuel flexibility are embedded from the design and newbuilding phase, if a conversion to a zero-carbon fuel is envisioned. This includes ensuring sufficient space and structural integration for alternative fuel systems, selecting materials compatible with a range of fuels to the extent possible, and designing fuel storage and supply systems that can be retrofitted with as low as possible disruption. Conducting high-level risk assessments early in the design phase can be an effective strategy to avoid potentially costly design changes later, depending on the extent of re-arrangement required.

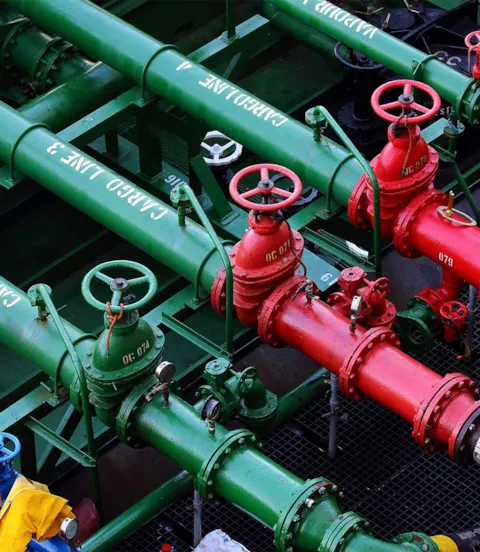

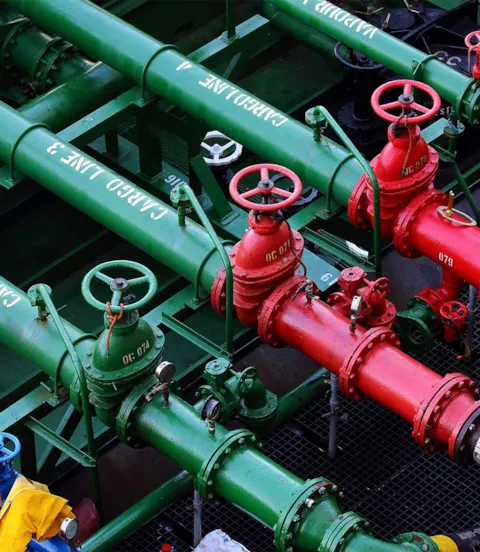

Risk mitigation measures for liquefied gases such as hydrogen and ammonia typically focus on minimizing and managing accidental and operational releases, and, to the extent possible, maintaining a distance from crew accommodation and workspaces. Detection systems for hazards such as gas leakages and fire are crucial safeguards to implement in relevant locations, enabling early warnings and the initiation of mitigating measures in case of occurrence. A practical and appropriate level of personal protective equipment (PPE) should be mandatory in hazardous areas.

Biodiesel: Immediate alternatives with specific risks

From a safety and design perspective, enabling a future switch from conventional fossil fuels to their biofuel counterparts involves practical and operational risks that need to be addressed to ensure compatibility of fuel systems with varying purity levels or slight differences in properties resulting from various production processes. Certain biodiesels have a shorter shelf life compared to conventional marine fuels, which necessitates careful storage and handling considerations. For some biofuels there may be a need for additional training of crew with regard to handling.

Switching safely from LNG

While fossil LNG may address some of today’s challenges, if a successful transition to next-generation fuels is intended, it depends on proactive planning and a design approach that anticipates both safety and regulatory demands. As parts of the industry looks towards fuels such as ammonia, hydrogen, and green methanol, safety must remain a top priority due to their unique risk profiles - ammonia’s toxicity, LNG's and hydrogen’s flammability and dispersion behaviour as well as its properties in both liquefied and compressed state, and methanol’s low flash point and near-invisible flame. Hydrogen is prone to leakage and can cause severe explosions when escaping. When stored in liquid form at ultra-low temperature of -253°C, it requires sophisticated vacuum-insulated pressure tanks that must meet even stricter requirements than LNG tanks. Interaction of liquefied hydrogen with air or other gases harbours additional safety risks that must be considered in the design of storage and processing systems. As an alternative to liquid storage, hydrogen may be stored in compressed form at very high pressure; here again, the containment system must meet strict requirements to reduce the likelihood of leakage.

Liquefied ammonia leakages may damage ship structures due to low-temperature embrittlement, likewise requiring suitable material choices for tanks, processing systems and their surroundings. Ammonia is also highly corrosive to certain types of commonly used construction materials, which has to be accounted for in material selection. The focus of the ship design should be on minimizing and mitigating ammonia releases.

Ensuring safe and prepared fuel transitions

Comprehensive risk assessments should be initiated early to guide technical decisions and ensure safe operations. These may include qualitative assessments like Hazard Identification (HAZID), Hazard and Operability studies (HAZOP), Failure Mode and Effects Analysis (FMEA), as well as quantitative studies like Quantitative Risk Assessment (QRA), Gas Dispersion Analysis (GDA) or Explosion Risk Analysis (ERA). It is also imperative that the organizations deciding to utilize alternative fuels evolve in parallel with the technical development, ensuring that aspects concerning crew training, operational procedures, and emergency preparedness all are ready to take on the transition to new fuels.

Switching from methanol

Methanol offers a relatively flexible platform for future fuel transition. It does not require cryogenic storage and can be handled with simpler infrastructure compared to LNG or hydrogen. Ships designed for conventional methanol from fossil sources can, without technical modification, switch to green or blue methanol.

While switching from fossil to green or blue methanol would not require any structural or system changes, continued compliance with evolving safety standards, emissions reporting, and certification frameworks must be factored in during the design phase.

Looking beyond methanol, a switch to zero-carbon fuels such as ammonia or hydrogen is technically more complex and would generally require significant redesigning of fuel storage, supply systems, and safety measures. These fuels come with different physical properties and risk profiles, demanding tailored containment, ventilation, and fire suppression systems.

Available interim guidelines for ships using alternative fuels (methanol, ammonia and hydrogen (draft)) are all based on the safety principles of the IGF code (International Code of Safety for Ship Using Gases or Other Low-flashpoint Fuels)

as a starting point. Until the respective interim guidelines are adopted into the IGF Code, a complete or partial alternative design and arrangements (AD&A) process will need to be undertaken for any alternative fuel project, depending on flag state requirements. The IMO’s risk-based AD&A process (MSC.1/Circ.1455) provides a basis for individual approvals.

Safe installation of onboard carbon capture and storage (OCCS)

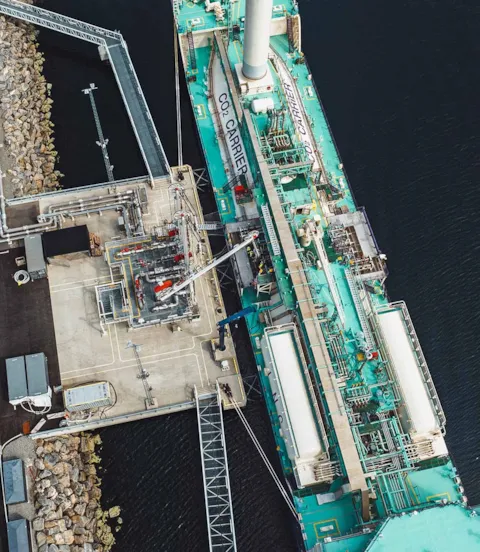

Carbon dioxide (CO2) captured from the exhaust gas stream using chemical solvents is purified and compressed for onboard storage. While CO2 is classified as a dangerous good by the IMDG Code and has recently been classified as toxic by IMO, its risks can be effectively managed with proper safety measures. CO2 displaces oxygen in the air, posing a risk of asphyxiation or intoxication, which must be mitigated through adequate ventilation and monitoring systems. The solvents and refrigerants used in the liquefaction and storage of compressed CO2 also require careful handling. However, with relevant training, PPE and safety

protocols, these risks can be minimized.

The installation of onboard carbon capture systems should adhere to guidelines covering exhaust pre-treatment, absorption processes, liquefaction, storage, and transfer systems. Regular maintenance and monitoring are crucial to prevent equipment failures and ensure the integrity of the capture and storage systems. Comprehensive crew training on the operation and emergency procedures related to OCC systems is essential to enhance safety and preparedness. These measures, combined with continuous regulatory updates and adherence to international safety standards, are vital for the successful deployment of onboard carbon capture technologies.

IMO plans to incorporate the application of onboard carbon capture in the IMO Lifecycle Assessment (LCA) Guidelines. DNV has published guidelines for the safe installation of onboard carbon capture, as well as comprehensive storage and classification rules, and offers its OCCS and OCCS Ready class notations. Flag state administrations have the final say on accepting these guidelines and may impose additional requirements for safe implementation on board.

- Ruben Soltvedt

- Ted PAGEL/Shutterstock

- Yara

- DNV