Bore’s next-generation RoLo ships will run on LNG

The Finnish owner Bore has ordered three new RoLo vessels from Wuhu Shipyard that will cater to the forestry industry’s needs by combining the latest LNG propulsion technology with an ice-strengthened, optimized and stiff hull and maximum cargo flexibility.

A small carbon footprint is a must

The Finnish shipowner Bore, established in 1897 and today a member of the Dutch Spliethoff Group, currently manages and operates a fleet of seven ships within a framework of long-time partnerships. Two of the seven Bore vessels are employed in trades transporting Finnish forestry products. With a focus on eco-friendly transport solutions as part of its corporate philosophy, Bore favours propulsion technologies that are state of the art and future-proof, especially in view of the IMO emission targets for 2030 and beyond. “We want to minimize our carbon footprint,” says Jørgen Mansnerus, Vice President – Marine Management at Bore Ltd.

Designed to customer specifications

Bore works very closely with its charter customers and caters to their specific needs, says Mansnerus. In early 2019 UPM approached Bore with a request to build three 7,000 dwt RoLo ships to operate in north-western European waters under long-term charter agreements. Key requirements for these vessels include ice class, LNG propulsion, high fuel efficiency, and strong structural reinforcements to manage heavy cargo transport.

New hybrid ship type

Versatility is an important requirement for the three new vessels, which will be 120 metres long and 21 metres wide, says Mansnerus. “RoLo ships are a hybrid ship type that combines the advantages of roll-on-roll-off ships with MPVs, loaded according to the lift-on-lift-off principle. Since these vessels are being purpose-built for carrying forestry products, they have to be able to load and unload various cargo types, including project cargo, in different ways, whatever infrastructure the destination ports can provide.” “From a class point of view the vessels are regarded as ‘dry cargo vessels’ suitable for carriage of a wide range of break-bulk, with a special focus on Ro/Ro cargo and containers, but also bulk cargoes,” Jost Bergmann, Business Director MPV at DNV explains. This is reflected by the class notations of these vessels: “+1A General dry cargo ship RO/RO Container DBC DG(B,P) LCS NAUT(NAV) Ice(1A) E0 Gas-fuelled Recyclable BIS BWM(T) TMON(oil lubricated)”. “These class notations also accentuate several other important operational and design features of the newbuilds, such as high ice class, advanced bridge design, LNG gas-fuelled engine plant etc,” Bergmann adds.

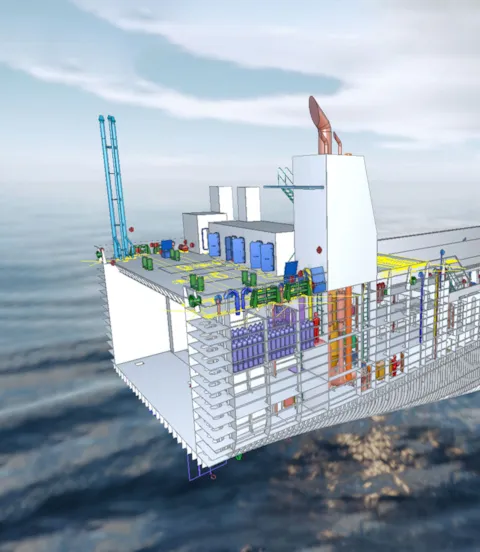

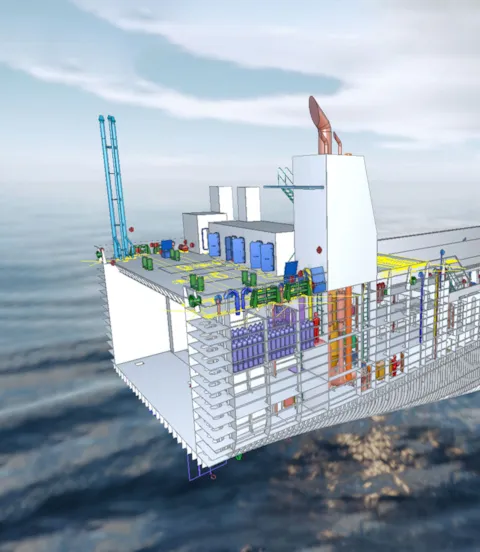

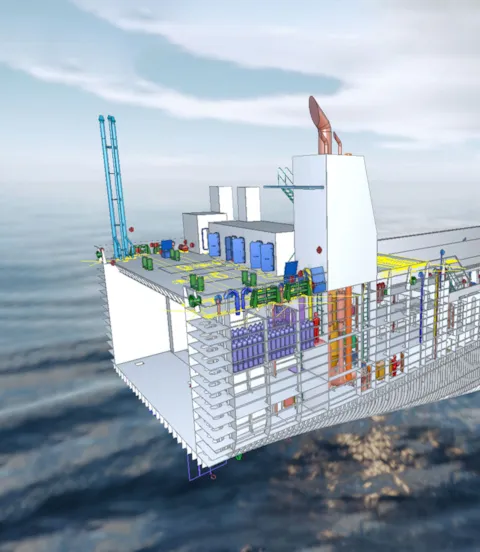

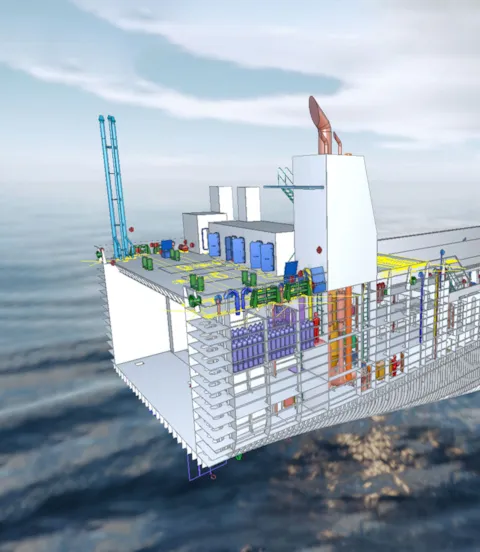

Maximizing cargo space

The stern ramp provides access for lorries and heavy cargo handling equipment. With the superstructure in far forward position, the cargo hold is also fully accessible from above by gantry cranes, and the lift-off hatch covers are strong enough to carry containers. The entire design focuses on maximizing cargo space, which means that all machinery is confined to the spaces below the large, open cargo hold. The crew accommodations will be in the bow section so all available spaces can be used.

“While these ships will carry a wide variety of forestry products, whether in break bulk form, on trailers or in containers, the transport of paper reels involves the most stringent requirements,” explains Jan Jaap Nieuwenhuis, Manager of the Design Department at Conoship International, the ship-design and engineering firm chosen for the project. “This is why our calculations for the design are based on paper reels as reference cargo.” For his engineers, this meant that the ship design needed to provide exceptional structural strength and rigidity to avoid elastic deformation in rough sea conditions or while loading and unloading heavy rolls of paper.

Everything below the RoRo deck

“As designers, we had to reconcile the space confinement below the ro-ro deck where all the machinery is located – the available height in that space is limited – with the need to accommodate the most suitable machinery,” explains Conoship ship architect Roel Blom. “It was helpful that the owner gave us some fairly clear specifications. Nevertheless, figuring out the detailed arrangements to meet the owner’s requirements while achieving the best design and structural strength – in other words, the best solution for this particular ship – took quite a bit of thinking and discussion,” he adds.

Because of its favourable environmental characteristics and relatively compact dimensions, a four-stroke dual-fuel engine was chosen. The Wärtsilä 34 will run on LNG as primary fuel, driving a gearbox with power take-off (VFD) for electrical power generation.

The diameter and length of the 250 cubic metre type-C tank were chosen to fit into the available space. “The tank capacity is sufficient for one round trip between Finland and western Europe,” says Mansnerus.

Paper requires special ambient conditions

Paper is highly sensitive to temperature and air moisture changes. “If we load paper in freezing temperatures in Finland, then take it to Spain, the ship will undergo a massive change of ambient conditions during the voyage. To protect the cargo from quality-damaging environmental influences, it is extremely important that the hatch covers and the stern ramp form tight seals when closed, and that the cargo hold is climate-controlled.”

Dehumidification of the cargo hold requires an extensive system of air ducts that needed to be integrated into the walls of the hold, explains Roel Blom: “Finding a way to route these ducts and gutters to drain moisture without compromising the structure of the ship, all the while meeting the required damage stability criteria, was quite a challenge.” The ducts ensure a continuous horizontal air flow throughout the entire cargo space without leaving any dead spots, he adds.

LNG fuel cuts carbon emissions

The use of LNG as the main fuel was clear from the beginning, says Bore VP Mansnerus: “It significantly reduces carbon output and almost eliminates all other emissions, and the market is growing. Furthermore, we believe that LNG is more than a transitional fuel. For our fleet, we believe that fossil LNG can eventually be replaced by biofuel as a drop-in. Biofuel can be produced from the by-products from paper and pulp manufacturing and other organic waste; a biofuel plant recently opened in Finland, and more will follow. Some other Scandinavian shipowners are already using biofuels.”

Operational efficiency

“The focus of our work was always on maximizing efficiency,” emphasizes Conoship design chief Nieuwenhuis. “This meant minimizing fuel consumption to achieve both, lowest fuel costs and minimizing emissions.” A low shaft rotational speed and a very large-diameter, optimized, controllable-pitch propeller along with an efficient hull shape and computer-assisted operation all help achieve this goal. Furthermore, the engine can operate either in continuous or in flexible RPM mode, depending on the situation, to further improve efficiency, Mansnerus points out. The design speed is 15 knots. “During the design development phase we performed extensive model basin test and advanced computer-based CFD analysis to optimize the design of the hull lines and the interaction between hull, propeller and rudder. We expect these vessels to be about ten per cent more efficient than conventional ships.”

Cooperation accelerates design

The owner, the future chartering partner, the design firm and DNV cooperated closely on this project. “We have worked well with DNV for many years and were confident that DNV had the right kind of expertise for this ship type and LNG propulsion,” says Mansnerus. “We have learned to trust their service and support and enjoy an excellent relationship with their international network.” The newbuilds will feature the DNV NAUT(NAV) class notation for bridge design and instrumentation.

DNV provided key expertise for the project, says Nieuwenhuis. “Collaborating closely with class, we were able to speed the project along by applying a ‘rolling approval process’ that avoided having to wait for design approvals. What is more, we had worked on an LNG project with DNV before and knew we could trust their LNG expertise.”

Cyber security first

While the three RoLo vessels feature advanced computer control and equipment monitoring features, Bore takes cyber security very seriously and restricts access to on-board systems to specific times and purposes, emphasizes Mansnerus. “We only allow individually assigned, temporary system access, for example for periodical downloads of engine operation data. Nobody gets continuous access to our data.”

More low-emission vessels are expected

The contracted builder, Wuhu Shipyard, sees in this project a proof of the expected renewal of the short-sea fleet, especially in Northern Europe where efficient, low-emission vessels are in high demand. “Using LNG as fuel for this ship type and size is still a novelty, giving our yard the opportunity to demonstrate our capabilities in handling this innovative technology as one of the forerunners”, says Zhang Zhao, General Manager at Wuhu Shipyard. “We are fully committed to making this project a success in close cooperation with the owners, designers and class DNV.”

Work at Wuhu Shipyard in China is progressing according to plan, and Bore expects delivery of the first RoLo ship in autumn 2021, with the remaining two following at three-month intervals. “Since our parent company is building some MPVs at the same yard in parallel, we have a strong team of eight company representatives on site to monitor progress. This has been very helpful during the travel restrictions caused by the pandemic,” says Mansnerus.

Jost Bergmann

Business director MPV

- UPM

- Conoship International