Sustainable ambitions for offshore wind support

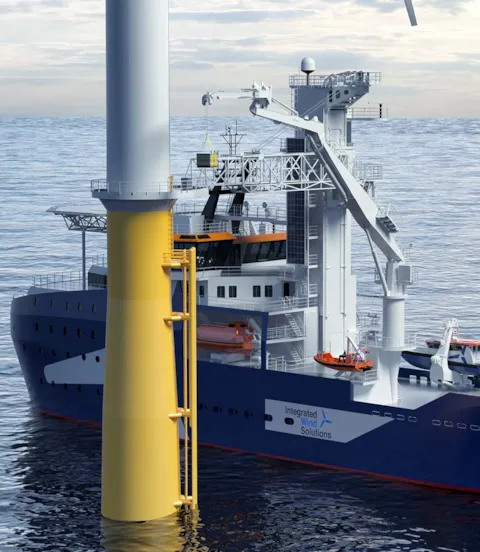

New company, new vessels, and new industry standards. Integrated Wind Solutions (IWS) aims to rewrite the rules for offshore wind support, launching a dedicated organization with tailor-made vessels offering unique operability, efficiency and environmental pedigree.

Christopher Andersen Heidenreich is struggling not to use the phrase “game changer”. “I think the word is overused, but these really are like nothing else in the industry,” the COO of IWS comments, referring to two “walk to work” commissioning service operation vessels (CSOVs) just ordered from China Merchants Industry (CMI), Hong Kong.

“They have been designed from a blank sheet of paper specifically to carry out their specialized functions in the optimal, most energy-efficient and safest way. Their operability is second to none and their environmental profile outstanding. “I give up,” he says, sitting back from the screen with a shrug and widening smile. “Okay, okay … they’re game changers.”

Renewable energy growth demands offshore wind support

When Integrated Wind Solutions launched its business in February the news sent a gust of excitement through the offshore wind segment. One factor was its origin – spawning from Norway’s Awilco, already a respected shipowner in segments including tankers, offshore oil service and car carriers – while the other related to its aim to build a portfolio of services covering the entire wind farm life cycle.

The ambition was crystal clear, but so was the perceived opportunity. “As society transitions towards renewables there’s huge potential within offshore wind,” says Heidenreich, who, having been a founding director of Fred. Olsen Windcarrier in 2008, knows his subject inside out. He points to the fact that the EU alone is planning to increase production capacity from around 12 GW today to more than 300 GW by 2050 in its bid for climate neutrality.

“That development means we now have larger and larger vessels installing larger and larger turbines, but not a fleet capable of servicing them with the efficiency, cost control and year-round operability they demand. “And that’s where we come in.”

Partnering for a best-in-class vessel paradigm

A new entry into a new business area has given Heidenreich and the team the chance to build a new breed of vessel – one tailor-made to perform for wind clients in demanding environments, with operations defined by safety, reliability and sustainability. The past year has been spent working with trusted partners to create that paradigm.

“We chose vendors that were best in class to produce a best-in-class vessel,” he says. “By the time they launch in Q1 and Q2 2023 (there’s also an option for another four with the yard), they’ll hit a growth market eager for a new standard of operation, providing a strong foundation for our ambitious growth plans.”

As society transitions towards renewables there’s huge potential within offshore wind, we now have larger and larger vessels installing larger and larger turbines, but not a fleet capable of servicing them with the efficiency, cost control and year-round operability they demand. And that’s where we come in.

So, what is meant by a new standard for CSOVs?

Exact specifications of the 90 m long, 19 m wide KONGSBERG-designed vessels remain under wraps, but Heidenreich reveals that a “breakthrough hull design” and “novel thruster configuration” are central to providing unique operability. To illustrate this, IWS studies forecast a stunning operability of 98% in the challenging environment of the UK’s Dogger Bank wind farm. The very latest 3D motion compensated crane (capable of handling loads of five tonnes) and motion compensated gangway, both from MacGregor, consolidate this performance, ensuring safe transfer of cargo and personnel in the most demanding conditions. In addition, safeguarding the environment is a central focus. This, Heidenreich says, is something of a “no-brainer”, pointing to the fact that the clients IWS will serve are in the renewables arena and will increasingly request zero-emissions service vessels.

Optimal environmental performance

To meet this demand IWS’s new assets will be zero emission capable from delivery.

Although constructed as plug-in hybrids, their sizable Corvus battery packs will allow for a degree of all-electric operation (for example, in and out of port areas), with the idea that they’ll transition to 100% electrical propulsion once the offshore charging infrastructure that many (including Heidenreich) see as inevitable has been installed at the wind farms themselves.

The use of the latest digital systems from KONGSBERG and other vendors (including digital twin technology) will help utilize data to optimize operations and energy savings, while added extras such as solar panels will ensure further green energy opportunity.

Heidenreich is also proud to point out that the CSOV design is amongst the first in the sector to achieve the Silent notation from DNV, ensuring minimal impact on marine life.

“We really do see this as a chance to create a model vessel,” he says. “Once launched they will be a tangible manifestation of both our ambition here and the level of service we will offer the marketplace. Why settle for anything less than the best?”

Offshore class expertise essential from day one

The IWS COO is at pains to stress that they certainly haven’t selected anything other than the best when it comes to partners on this “very collaborative” project. He admits some eyebrows may have been raised by the decision not to build locally (with reference to Norway’s outstanding offshore pedigree), but counters that CMI has a first-class reputation for constructing highly specialized vessels, including within the wind sector, and offered the best combination of both price and quality.

“We’ve worked with them before at Awilco,” he says, “so we’re very confident in the level of quality we can expect.” The same, he notes, is true of DNV. “DNV is the most experienced class society for offshore and we were keen to establish a close working partnership right from the very beginning – discussing design, requirements, specifications and, what’s more, using the team as a sparring partner in the development and refinement of our ideas and overall concept. The fact they have a good presence in China also helps, as do their connections throughout the industry, and particularly with our other key vendors.”

Heidenreich smiles: “The best team delivers the best results. We appreciate that collaboration and we know, without a doubt, that our clients will – with energy-efficient, cost-effective and highly operable wind service vessels from 2023 onwards.”

Fully comprehensive wind farm support

Looking beyond the next two years, IWS aims to evolve quickly – propelled by both industry demand and investment capital from a stock market listing in Oslo – to become, in their COO’s words, “one of the major suppliers of high-quality tonnage and services for the commissioning, operation and maintenance phases of wind farms.”

Although it’s early days, Heidenreich says the initial strategy will focus on tailoring and adding services to meet client needs, essentially “making their lives easier” with efficient, cost-effective, safe and trusted operations. Europe will be the chief hunting ground, but he certainly won’t rule out global development as the business evolves.

“We really are approaching this market in a new way, with a next-level vessel concept that delivers huge value,” he concludes.

Arnstein Eknes

Business/Segment Director - Special Ships

- Integrated Wind Solutions