Open Simulation Platform – the next generation of digital twins

Increasingly advanced and integrated vessel systems offer great benefits to shipowners and operators. Key maritime stakeholders have found a way to ensure these systems can be tested before being installed.

The Open Simulation Platform Joint Industry Project (OSP), founded in 2018, addresses the challenge of testing new and advanced vessel systems before they are installed on board. The project was initiated by DNV GL, Kongsberg Maritime, the Norwegian University of Science and Technology (NTNU) and SINTEF Ocean and has also brought together 20 further industry partners in what promises to be a game-changing effort to maximize the benefits of digital twin technology.

Co-simulation of multiple models

The goal for the OSP is to establish a standard for models and simulations in the maritime industry, enabling both the reuse of models and collaborative system simulations to solve challenges in the design, building and operation of today’s and tomorrow’s ships.

“The Open Simulation Platform is an open-source software code and will be a game changer for the industry when it comes to the utilization of simulation tools and virtual prototyping as an integrated part of the value creation process. It allows for co-simulation of multiple models without the need for remodelling or transferring models between their application software environments,” says Svein Kleven, Senior Vice President at Kongsberg Maritime.

DNV GL will host the OSP ecosystem, providing a neutral space for industry collaboration, with an eye to future classification services for cyber-physical systems and components, as well as future model-based advisory services. “We are building the Core Simulation Environment (CSE), a co-simulation engine based on decades of experience from all founding partners. It combines these legacies with new standards from the automotive industry. The CSE will be launched as open source to the industry in 2020, in order to drive standardization and enable companies to work on the same basic platform,” explains DNV GL’s Research Programme Director Øyvind Smogeli, who is managing the project on behalf of the partners.

“Software and systems integration issues can create challenges throughout the newbuilding and operational phases, leading to expensive delays, slowing innovation, and causing undesired incidents and downtime. There is a growing need to understand how different systems work together to help owners avoid costly consequences of unforeseen complications,” says Pierre Sames, Group Technology and Research Director at DNV GL. “For example, as owners seek to equip vessels with more sophisticated digital solutions offered by different suppliers, they become more vulnerable to software and systems integration failures,” he adds.

Assessing emergent properties using advanced digital twins

The OSP uses digital twins comprised of a large set of interconnected models and components. “The beauty of the OSP concept lies in the interoperability of models from all stakeholders and modelling tools, and the collaboration opportunities this offers. A digital twin component would include engineering models of the equipment physics and control system software, as well as emulated control system hardware, human–machine interfaces, and control panels, making it possible to perform virtual commissioning, configuration and testing in a collaborative effort on the platform,” says Øyvind Smogeli.

The OSP approach offers more than what is usually associated with digital twins, explains Smogeli. “Comparing data from the real asset with the digital twin in order to refine the twin and perform condition monitoring is important, but a digital twin cannot monitor or detect system failures in complex systems or predict the effect of changes to software or other system elements. The OSP’s ability to assess emergent properties represents the next-level digital twin.”

Emergent properties exist in a system only because of the interaction of its parts. For example, an engineer might do a software update for a thruster, which may be fine in isolation, but if it’s not tested in an OSP-like twin environment, it could have a mission-critical impact through other systems on the vessel. Such system issues are difficult to deal with and typically lead to expensive downtime for ships and rigs.

The aim of the OSP is to resolve these issues by incorporating engineering models and the actual control system software from all manufacturers into the digital twin.

24 active partners and growing

Since work began in 2018, the OSP has also generated interest among other stakeholders from all over the world. “Today, we have a total of 24 active partners, including suppliers, sub-suppliers, energy companies, shipyards and owners, and there is an open invitation for new partners to join the project,” says Smogeli.

One key challenge has been to ensure the integrity of intellectual property rights among partners. “Everyone agrees that managing software integration issues requires some measure of transparency between stakeholders,” he says. “But we recognize that for the OSP to become a truly collaborative platform, all stakeholders must trust that their proprietary software and solutions remain safe and undisclosed.”

Open-source collaboration on Veracity

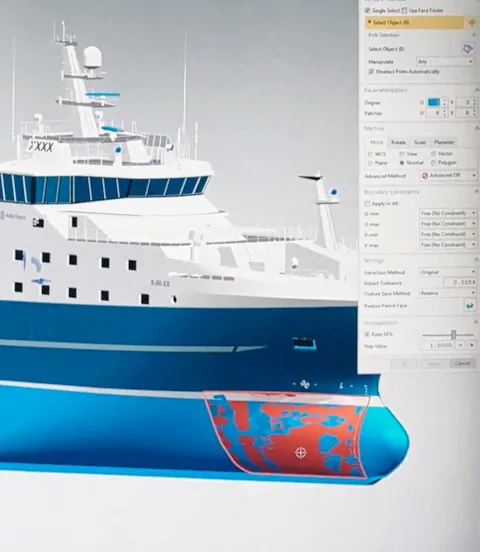

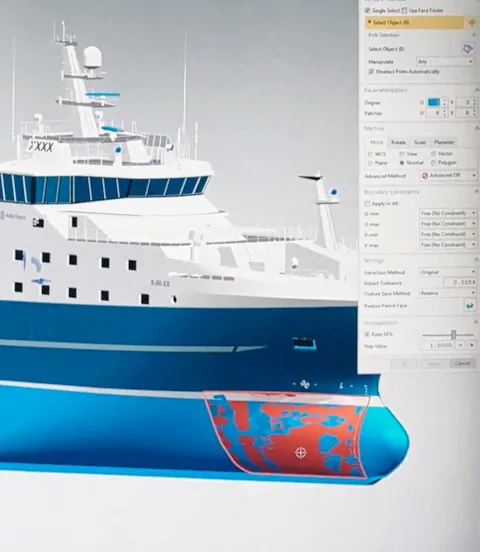

“We are currently developing three use cases to give users a sense of how the OSP platform works,” says Smogeli. “These include the design of a hybrid ferry propulsion system, virtual commissioning of a coastal service vessel, and planning of a subsea crane operation.”

The full OSP ecosystem – incorporating the Core Simulation Environment, the model catalogue and all needed platform mechanisms – will be hosted on DNV GL’s open industry data platform Veracity. This provides a secure and neutral collaborative space for all stakeholders, allowing any partner to use the models they have been granted access to for their own purpose, and enabling a group of partners to establish co-simulation without exposing the inner workings of models or control systems software.

For Remi Eriksen, Group President and CEO of DNV GL, the project represents a good example of how the industry can work together to solve common challenges. “At its core, the OSP is a tool for the industry to innovate and co-create next-generation vessels on a platform that has clear benefits for each stakeholder,” he says. “But we also recognize that, thanks to the introduction of new digital technologies that enable everything from automation to zero-emissions propulsion systems, the OSP may also play an important role in helping the industry to improve safety and environmental performance. If we get it right, the OSP could have a profound impact on how the industry works together in the future.” In February 2020 the platform was awarded the Riviera Maritime Media’s OSJ Safety Award, highlighting the effective collaboration between the different stakeholders.

- Key image - ©LegasC - stock.adobe.com

- Side image 2 - DNV GL

- Side image 3 - DNV GL