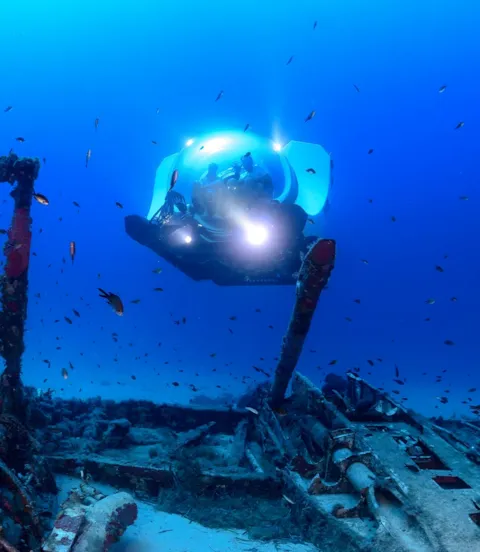

Exploring the Deep Blue with submersibles

Exploring sunken wrecks and observing sea life are highlights of cruise and superyacht trips. Builders and owners of submersibles turn to DNV GL to scrutinize the safety of their craft and ensure trouble-free subsea fun.

Of all the pleasurable things you can do when travelling on board a cruise vessel or mega yacht there is hardly anything that beats diving down into the abyss in a custom submersible to watch exciting sea life or explore sunken shipwrecks. If you trust the craft, that is. But how can you trust a submersible that will take you far down into the black depths of the sea? By making sure there are plenty of redundant life-supporting systems, and by having the craft vetted, trialled and scrutinized by experts who know exactly what to look for.

The role of class in ensuring safe diving

Diving depths usually range from 100 to 1,000 metres, in some cases even deeper. The water pressure at those depths is enormous. Making sure nothing will ever go wrong down there is of utmost importance. The owner wants to be able to assure the passengers – up to seven people, depending on the size of the craft ‒ that they can relax and fully enjoy the adventure, knowing they will resurface safely.

Designers of leisure and research submarines are highly specialized experts who customarily engineer wide safety margins into their craft. For example, the standard operational endurance of such a submarine is ten hours, but the life support systems are designed for a minimum of 96 hours, explains Jonathan Struwe, Senior Inspection Engineer and Surveyor for Pressure & Underwater Technology at DNV GL. “Before these crafts are deployed with people on board, the pressure hull and all pressurized components undergo a test that significantly exceeds the design diving pressure. All systems are tested during various manufacturing stages, then again under controlled diving conditions, and finally at design diving depth. The role of the class society in all this is to ensure an independent critical review of the design by considering any foreseeable failure modes and load cases, reconfirmed and proven by load and functional tests.”.

“Safety is always the first priority,” Roy Heijdra, Marketing Manager at U-Boat Worx (UBW) emphasizes. “U-Boat Worx involves the class society from the start of the design process all the way to the final sea acceptance trials, and where needed the suppliers have DNV GL’s workshop approval.” Customers want nothing but the highest safety for themselves and their friends and loved ones, he adds, and compliance with IACS class society rules ensures international recognition, apart from providing worldwide access to the expertise of DNV GL’s global surveyor network.

The principal design philosophy underlying the DNV GL rules is that redundancy is provided for all essential systems so that in the unlikely event of a failure, they all remain functional and safe surfacing is guaranteed, Struwe comments. “This approach is comparable to the safety standards of the aircraft industry.”

Patrick Lahey, President of Triton Submarines, confirms it is essential for a manufacturing company to demonstrate adherence to the strictest standards. “The IACS class society rules are the only way our clients can be assured our products meet an internationally accepted set of standards and can be used to carry their friends, family members and guests on exciting adventures underwater in absolute safety.”

All for a trouble-free diving experience

During operation these submersibles are always supported by a surface vessel, and diving is restricted to specific, certified environmental limits regarding sea state, wind speed, sea currents and temperature.

Furthermore, current manned submersibles used for mega yachts and cruise liners are usually maintained by the manufacturer. DNV GL carries out annual inspections with a focus on the condition of all essential and safety-related systems, including a trial dive involving functional tests. An even more comprehensive inspection takes place every five years. In case of safety concerns the craft may be suspended from classification until all issues have been resolved.

Of course, safety isn’t all that matters to people taking a submarine dive. The pressure hulls of leisure submersibles are usually designed to provide the clearest possible view, and the interior environment is comfortable with a pleasant atmosphere to ensure a truly memorable diving experience, including entertainment equipment.

While the potential size and operating depth of a submersible are theoretically unlimited, the designers of a specific craft must make sure the craft can be accommodated within the space provided on board its ‘mother ship’ and the cost of the unit remains within the overall budget. “We must work closely with the yacht builders to ensure the integration challenges have been carefully thought through and addressed,” says Lahey. “But the greatest challenge Triton faces is managing client expectations, such as turnaround time from order placement to the delivery of the finished submersible. Since every craft has unique features, it takes time to design, engineer and build them.” UBW’s Roy Heijdra notes: “We see a growing interest in the superyacht market as manned submersibles become more and more accepted. As we are expanding our market to include smaller yachts, space and weight has become an issue. We have been developing and marketing several smaller submarines, alongside the current U-Boat Worx range.”

Advanced technology provides many opportunities to make the diving experience even more thrilling, Lahey adds, but incorporating special features requires more development time, requiring patience on the owner’s side.

Diving to record depths

Triton is known as the builder of the Deep Submerge Vehicle (DSV) Limiting Factor, which on 28 April 2019 set a new record for the deepest manned descent, reaching 10,927 m ± 8 m in the Challenger Deep of the Mariana Trench as part of the Five Deeps Expedition, piloted solo by Victor Vescovo. Five days later, Patrick Lahey and Jonathan Struwe performed the deepest-ever marine sea trials and combined salvage operation to retrieve an unmanned scientific lander, an auxiliary vehicle that had accompanied the record dive and become stuck on the sea bottom. Struwe was responsible for the classification of Limiting Factor and participated in the dive, which doubled as the craft’s DNV GL Commercial Certification Dive, to confirm its fitness for the extreme conditions at Earth’s deepest point. Having explored the Challenger Deep and the Sirena Deep of the Mariana Trench, The Five Deeps Expedition also reached the Tonga Trench in the South Pacific, which is nearly as deep as the Mariana Trench, and recently reached the Molloy Deep in the Arctic Ocean via passing and visiting the wreck of the Titanic. The entire programme was completed in August 2019.

“Everyone at Triton recognizes the importance of the relationship we have with DNV GL and the critical role third-party accreditation plays in enhancing the safety, efficacy and effectiveness of our products,” says Lahey. “No project underscores the significance of this relationship more fully and completely than the Five Deeps project and the unprecedented ‘unlimited diving depth’ noted on the DNV GL certificate of this craft. We are immensely proud of achieving this distinction and recognize DNV GL was a critical part of our success.”

- Key image: Rob Aarsen/U-Boat Worx

- Side image 2: U-Boat Worx

- Text image 1: Triton Submarines

- Text image 2: U-Boat Worx

- Side image 3: U-Boat Worx

- Text image 3: Triton Submarines