Gauging the cost of LNG

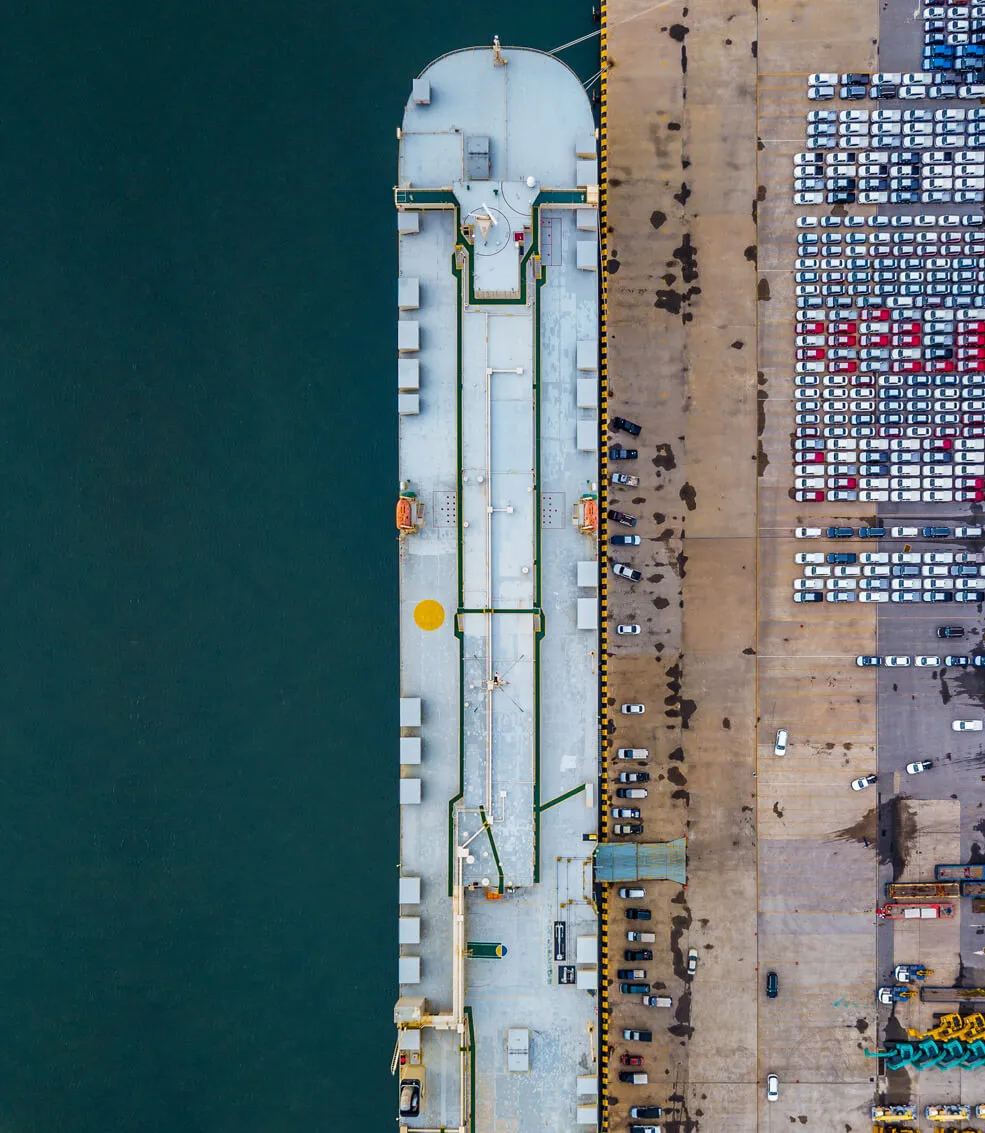

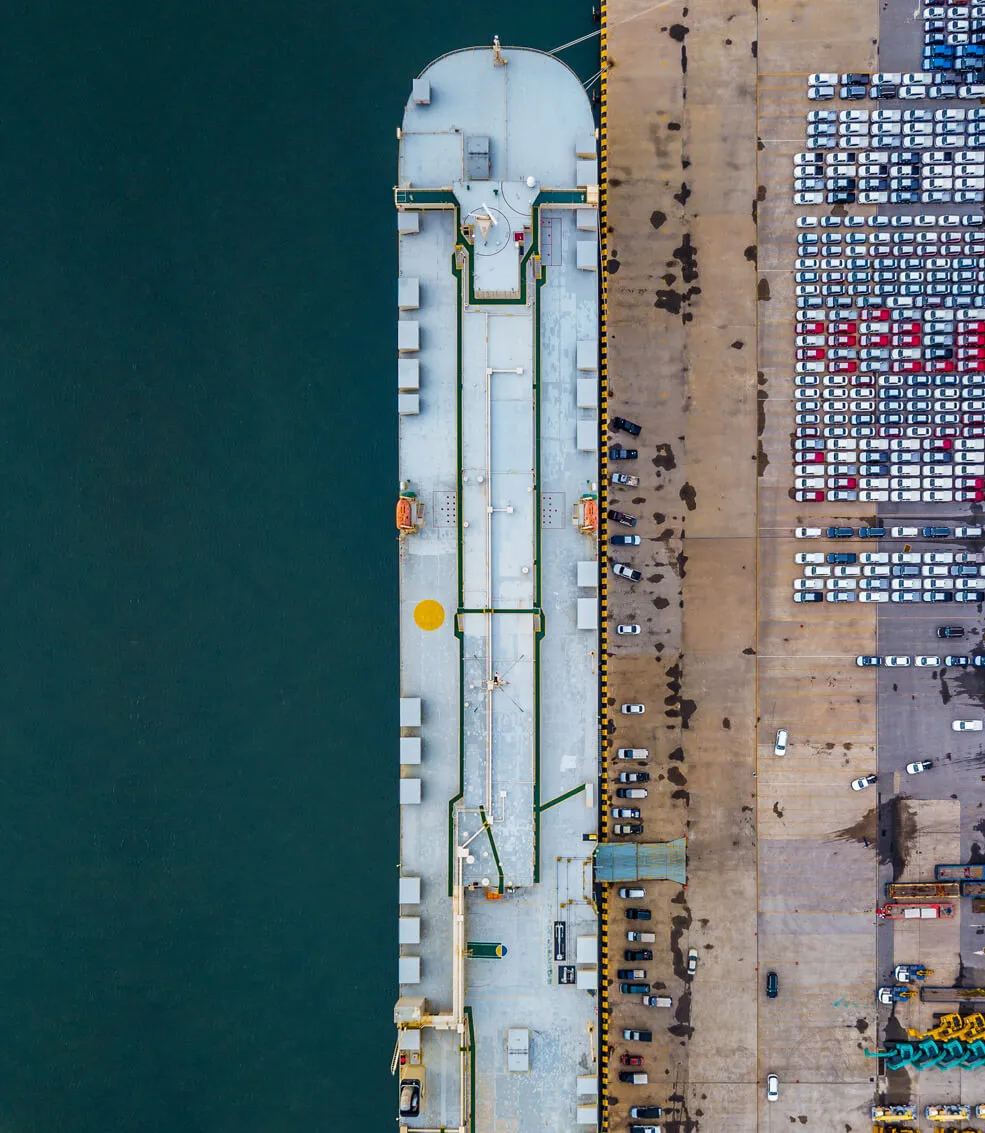

In a feasibility study, DNV GL has attempted to calculate the business case for an LNG-fuelled pure car and truck carrier operating between Europe and North America. Various scenarios are conceivable.

As the shipping industry enters a new age of strict environmental regulations, owners must choose a fuel that will be compliant and financially supportable. DNV GL’s feasibility study assumes a pure car and truck carrier (PCTC) operating between Hamburg, the US and Mexico. Two LNG engine and tank configurations optimized for 16 and 18 knots were compared with a conventional engine with a scrubber system in terms of total capital and operational expenditures (CAPEX, OPEX). The calculations factored in all costs associated with either type of propulsion system and are based on current market prices of equipment.

A number of factors that can have a significant impact on the final results remain unpredictable, including the development of fuel prices, which will depend on demand as well as potential political measures. The study therefore considered various but not all conceivable price scenarios. While low-sulphur fuel oil (LSFO) will likely be the most expensive compliance option, the cost performance of LNG ranges between LSFO and HFO, depending on the assumed LNG market price. In the most favourable scenario, LNG approximates the cost of the scrubber-equipped ship, especially so in the 18-knot example. However, it should be noted that LNG offers additional benefits in terms of particulate matter and CO2 emissions. DNV GL therefore included calculations of potential savings under an assumed CO2 taxation or trading scheme, which would further improve the feasibility of LNG.

Additional considerations

The DNV GL study may thus serve as a high-level basis for continued discussion only. While its assumptions are believed to be balanced and reasonable, there can be no guarantee that unexpected events or political decisions will not change the scenario significantly. The difference between LNG and the scrubber option is small, and LNG is believed to pose lower general risks and be the most future-proof option currently available. Options for further reduction of the LNG CAPEX include more frequent bunkering in favour of smaller tanks, which would also reduce the loss of cargo space. Risks associated with scrubbers relate to sludge disposal, restrictions applying to open-loop systems, and maintenance; additional investments for NOX Tier III compliance should be kept in mind, as well. DNV GL offers more specific and accurate calculations for particular ships and operating patterns.